Diversification of the product range demanded by the packaging market means that print companies face a constant increase in the share of short and medium runs. If these jobs are to be produced sustainably and efficiently, an objective and holistic comparison of the print and process costs is imperative. Against this background, Koenig & Bauer Durst has teamed up with the Fraunhofer Institute for Material Flow and Logistics (IML) to examine the opportunities for and challenges facing digital and offset printing from the supply chain perspective. Senior product manager Oliver Baar and strategy and business development manager Jochen Sproll from Koenig & Bauer Durst explain the conclusions of this analysis and what the results mean for the industry as a whole.

Diversification of the product range demanded by the packaging market means that print companies face a constant increase in the share of short and medium runs. If these jobs are to be produced sustainably and efficiently, an objective and holistic comparison of the print and process costs is imperative. Against this background, Koenig & Bauer Durst has teamed up with the Fraunhofer Institute for Material Flow and Logistics (IML) to examine the opportunities for and challenges facing digital and offset printing from the supply chain perspective. Senior product manager Oliver Baar and strategy and business development manager Jochen Sproll from Koenig & Bauer Durst explain the conclusions of this analysis and what the results mean for the industry as a whole.

The industry is looking back at a few turbulent months. Where do you see the biggest challenges confronting printers today?

Oliver Baar: The most significant aspect is almost certainly substrate availability, where we can even speak of paper rationing in some cases. Shortages like this drive cost pressures, but the print companies are neither willing nor indeed able to pass on the full additional cost to their customers. At the same time, the folding carton market is moving in the direction of ever shorter runs, shorter product lifecycles and even greater diversification. And last but not least, printing companies, too, are struggling with the general shortage of qualified employees and the massive rise in energy costs.

Short runs – is that not actually a point where digital printing could make use of its particular strengths?

Jochen Sproll: Yes, of course. But we wanted to look at the situation in more detail, and to consider the whole supply chain rather than just the printing costs. Our focus was therefore also directed at, among other things, the current developments and the cost of total value chain waste. It is important to keep an eye on storage costs and not just on waste during the production process. These are all factors that determine whether a particular run length can be produced more efficiently in a digital or offset process.

How exactly did you perform the analysis?

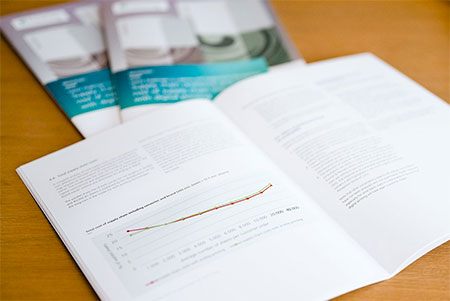

The whitepaper directs its focus at the entire value creation chain covered by folding carton production and examines the conditions under which digital printing is able to make use of its strengths

Jochen Sproll: First of all, it was very important for us to work on this project together with an external partner with corresponding supply chain expertise, in order to obtain a truly objective picture – and we found that partner in the Fraunhofer Institute for Material Flow and Logistics in Dortmund. We then set about developing a calculation model reflecting the entire supply chain. This model was fed with real production data from a printing company, with data relating to the digital printing process from us, and with information covering the whole logistics and supply chain side from Fraunhofer.

Oliver Baar: Being able to work with real production data from an actual printing company brought great benefits. The company granted us unfiltered insights into its processes and its cost and run length structures, which meant that, instead of a purely theoretical evaluation, we could produce a real-life case analysis for an industrial application. This makes the study far more than just a comparison of machine costs – instead, it draws its comparisons across the entire production process, including the associated supply chain. It is simply the case that the upstream and downstream processes, in particular, must play a significant role in any well-founded comparison. And that is what makes the whitepaper so exciting.

Why is that so important?

Oliver Baar: Well, there is no doubt about the huge advantages of digital printing. It is fast, it is flexible and it is individual. There are, however, also potentially problematic factors. Let’s just think about the logistics, for example. If you are producing more and more small jobs, that will also mean more transport processes. On the other hand, digital printing enables you to avoid unnecessary overproduction and waste. Both aspects must be taken into account in a comparison. And that is why I believe that the study that we have conducted into this is objective and valuable to brands and converters as they assess their waste and sustainability credentials.

Does sustainability also play a role?

Jochen Sproll: Definitely! In two respects, in fact. Sustainability is one of the three pillars of Koenig & Bauer’s Exceeding Print strategy, but at the same time also one of the key demands coming from our customers in the market – and that with the expectation of clear proof by way of certifications or the like. This means that our task as a press manufacturer is to offer our customers not only a technically optimal solution, but also the best solution for sustainable production. And in this context it becomes evident, for example, that digital printing with its short runs and reduced makeready times enables considerable savings – if fewer waste sheets are thrown away during makeready, we are also wasting less ink and substrate. What’s more, both print companies and brand owners can reduce their warehouse capacities if overproduction is avoided, and there are no additional products to be held in intermediate storage and possibly sent to waste after all at a later date. These savings are, of course, effective in terms of both costs and sustainability.

“Our task as press manufacturer is to offer our customers not only a technically optimum solution, but also the best solution for sustainable production.” – Jochen Sproll

When all these factors are taken into account, for which run lengths does digital printing have an edge?

Jochen Sproll: It’s not possible to generalise, of course. That said, our analysis did reveal that, after taking all process costs into account, a digital press like our VariJET 106 can actually be more profitable for medium runs. People tend to consider just the costs of printing. The threshold below which it becomes meaningful to choose a digital press is then often found at around 3,000 sheets. If we consider the overall process costs, however, the break-even point shifts to run lengths totalling between 6,000 and 10,000 sheets.

Oliver Baar: And that, in turn, opens up a whole new range of options for a print company’s existing offset presses. The investment in a digital press must not be viewed in isolation, because it has the potential to increase the overall volume of production. If a company takes short runs out of its offset process and transfers them – for example – to a VariJET, it achieves three things: in addition to the various benefits that have already been mentioned several times, the additional option of digital printing enables the company to enhance the portfolio of services it offers to customers, and at the same time to produce higher volumes at lower costs using its existing presses. A process evaluation that takes the company’s entire production output into account is immensely important for such a decision.

But that also goes to show that the decision to embrace digital printing means more than just the installation of another press. Do print companies also need to reorganise their in-house processes if they take this step?

Oliver Baar: Definitely. To be able to exploit the benefits of digital printing to the full, internal processes must also be adapted accordingly – similarly digitised, so to speak. You are unlikely to find people still walking around with paper job dockets in their hands nowadays, but a leaner workflow brings benefits for overall production. The decisive point is: if my digital press is going to be printing more jobs than I used to handle in offset, my fixed costs per job cannot remain constant. Adapting my organisation to process more jobs also means accelerating the passage of each individual job through the company – through automation, with workflow systems, via a web-to-print shop, by way of effective reporting. It represents a demand that digital printing must satisfy, but also an opportunity for business as a whole.

Jochen Sproll: Optimum use of the technology triggers a chain reaction: brand owners can call up smaller batches, the print company is in a position to produce them efficiently, less intermediate storage capacity is needed and the risk of obsolescence is minimised. In this way, less waste is produced and the result is a more environment-friendly overall process.

“The investment in a digital press has the potential to increase the overall volume of production.” – Oliver Baar

Does the experience gained in folding carton production permit conclusions to be drawn for other market segments?

Jochen Sproll: I think so, yes. In corrugated packaging, for example, we have a very similar situation. This is why it makes sense to include the factors of waste and flexo plate costs in the direct cost comparison in order to obtain a more realistic picture of the full value creation chain in this case as well. Even the substrate itself is a relevant variable, because the contactless digital printing process by the Delta SPC 130 enables thinner topliners to be used without limiting the functionality of the corrugated packaging. On the other hand, the ink costs do, of course, become higher, but they will eventually play only a marginal role in the overall evaluation. Therefore: it always pays to factor the entire value creation chain into your analysis.

Diversification of the product range demanded by the packaging market means that print companies face a constant increase in the share of short and medium runs. If these jobs are to be produced sustainably and efficiently, an objective and holistic comparison of the print and process costs is imperative. Against this background, Koenig & Bauer Durst has teamed up with the Fraunhofer Institute for Material Flow and Logistics (IML) to examine the opportunities for and challenges facing digital and offset printing from the supply chain perspective. Senior product manager Oliver Baar and strategy and business development manager Jochen Sproll from Koenig & Bauer Durst explain the conclusions of this analysis and what the results mean for the industry as a whole.

Diversification of the product range demanded by the packaging market means that print companies face a constant increase in the share of short and medium runs. If these jobs are to be produced sustainably and efficiently, an objective and holistic comparison of the print and process costs is imperative. Against this background, Koenig & Bauer Durst has teamed up with the Fraunhofer Institute for Material Flow and Logistics (IML) to examine the opportunities for and challenges facing digital and offset printing from the supply chain perspective. Senior product manager Oliver Baar and strategy and business development manager Jochen Sproll from Koenig & Bauer Durst explain the conclusions of this analysis and what the results mean for the industry as a whole.

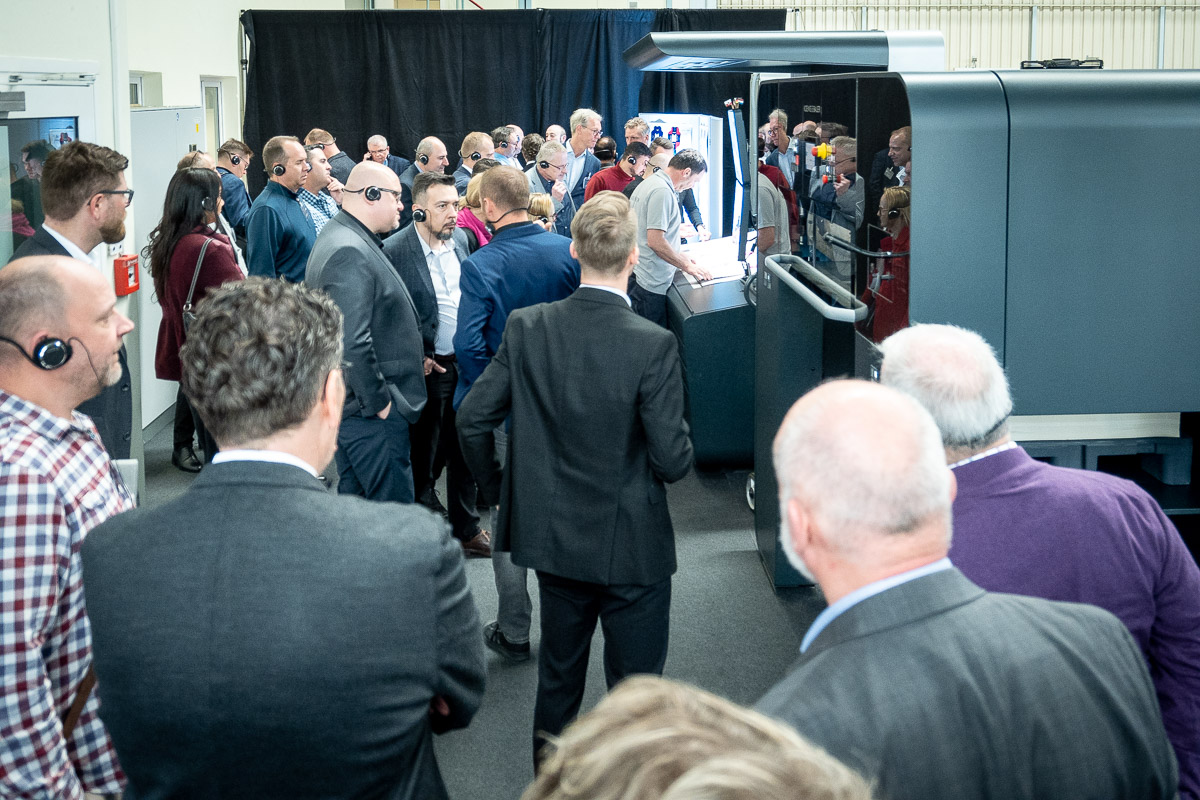

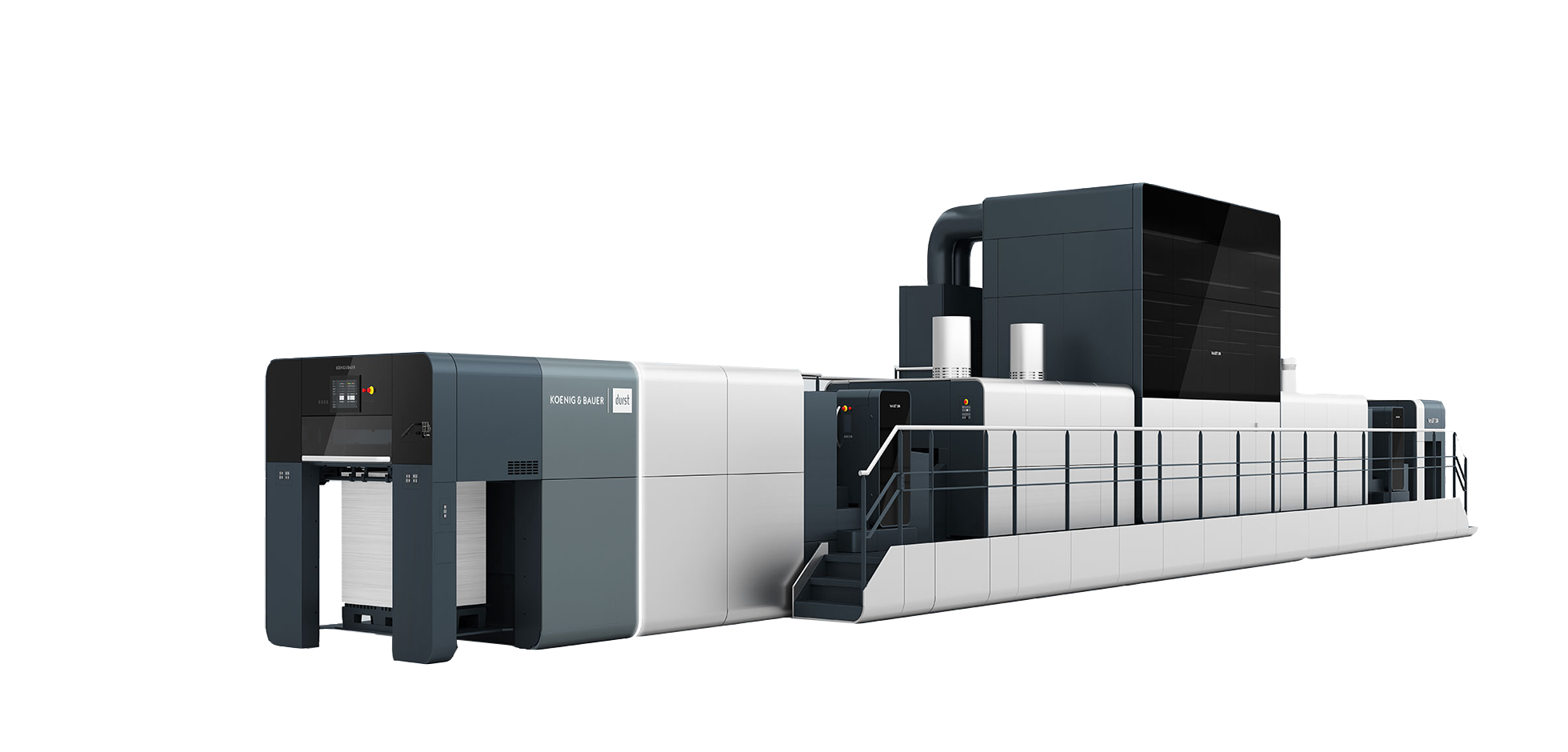

Two technology leaders in printing and packaging joined forces three years ago to pool expertise and resources in a research and development project costing millions of euros. Durst and Koenig & Bauer formed the joint venture company – Koenig & Bauer Durst – in 2019. The result of their seamless integration and cooperation was the worldwide launch of the VariJET 106 in October 2021. This is the background to the challenges and their achievements.

Two technology leaders in printing and packaging joined forces three years ago to pool expertise and resources in a research and development project costing millions of euros. Durst and Koenig & Bauer formed the joint venture company – Koenig & Bauer Durst – in 2019. The result of their seamless integration and cooperation was the worldwide launch of the VariJET 106 in October 2021. This is the background to the challenges and their achievements.