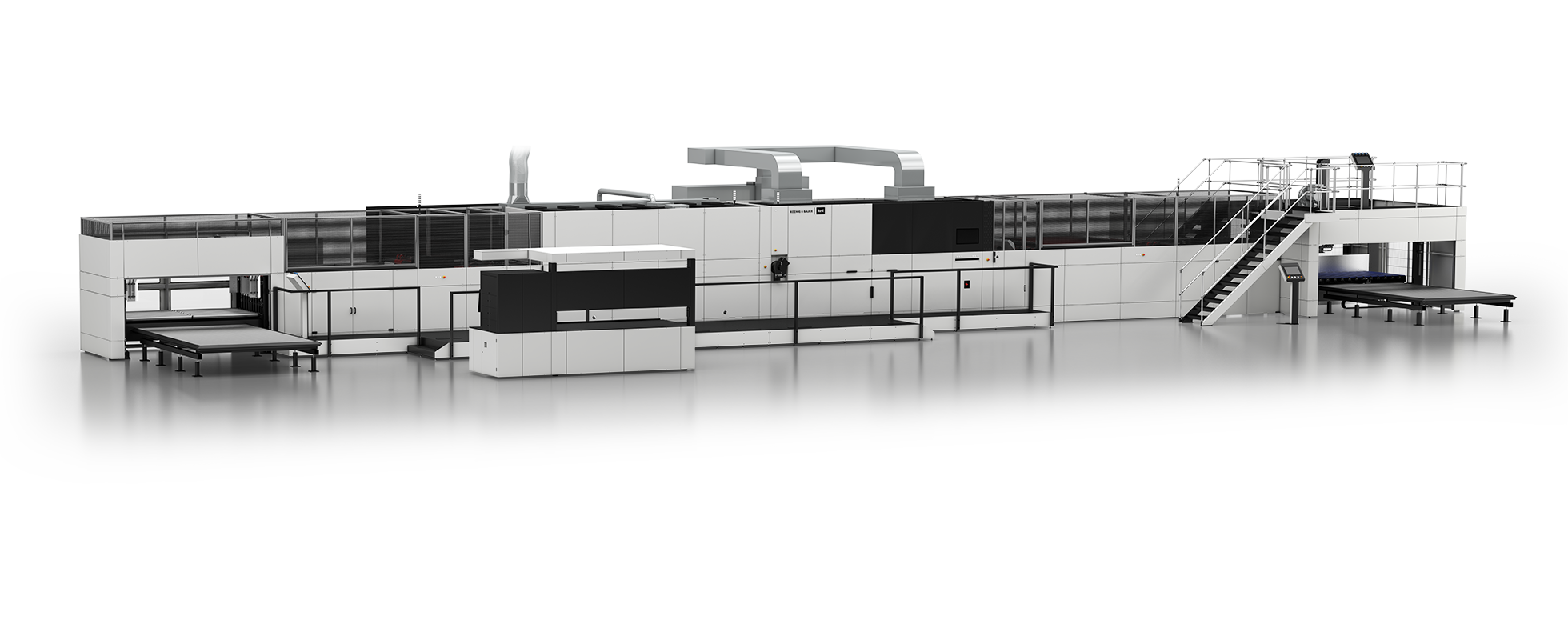

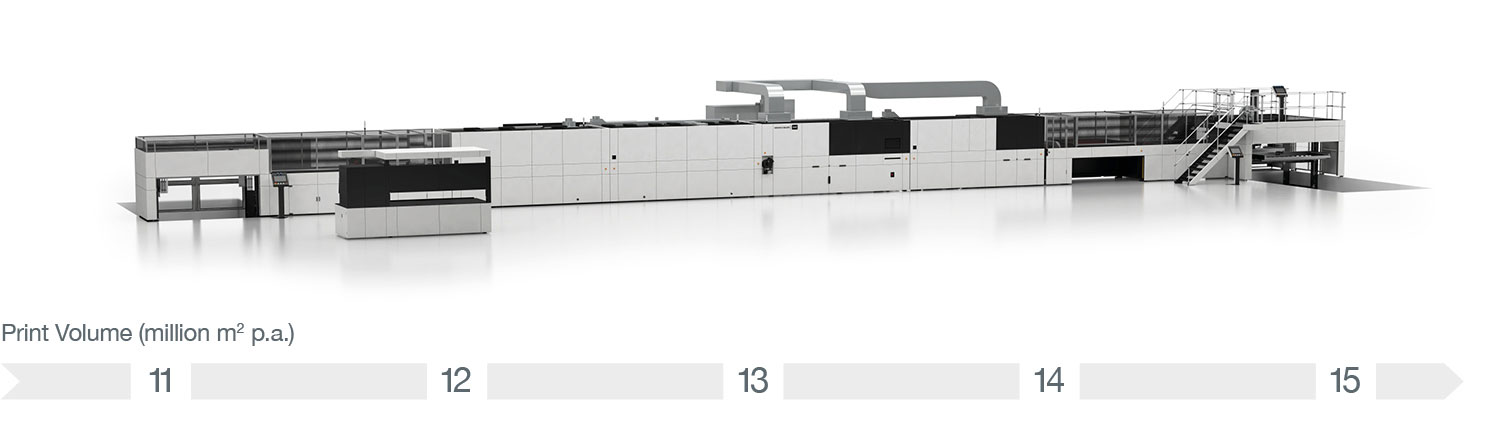

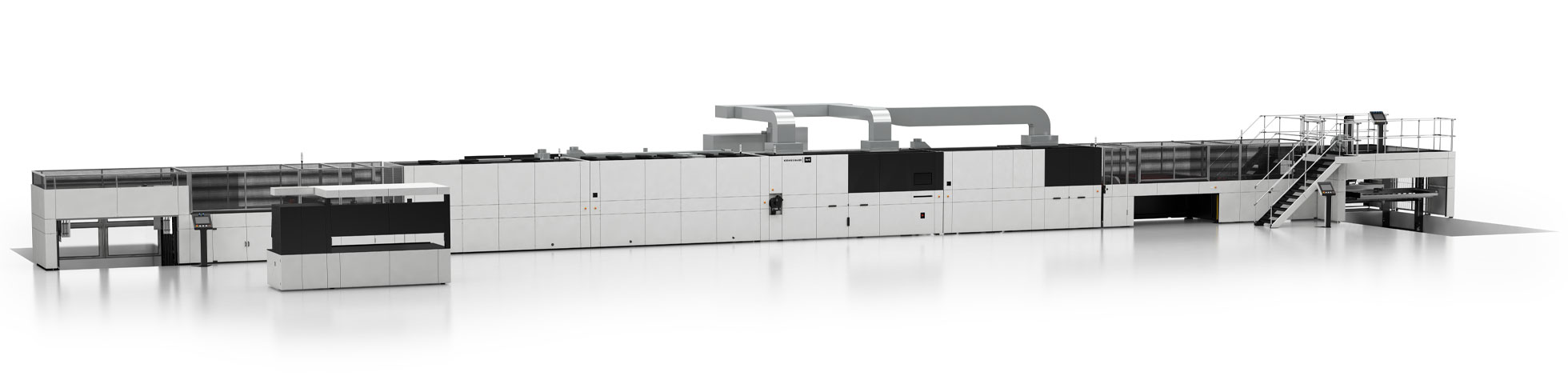

Based on the latest generation of single-pass printing, we now bring fully automated digital single-pass technology to the corrugated board industry.

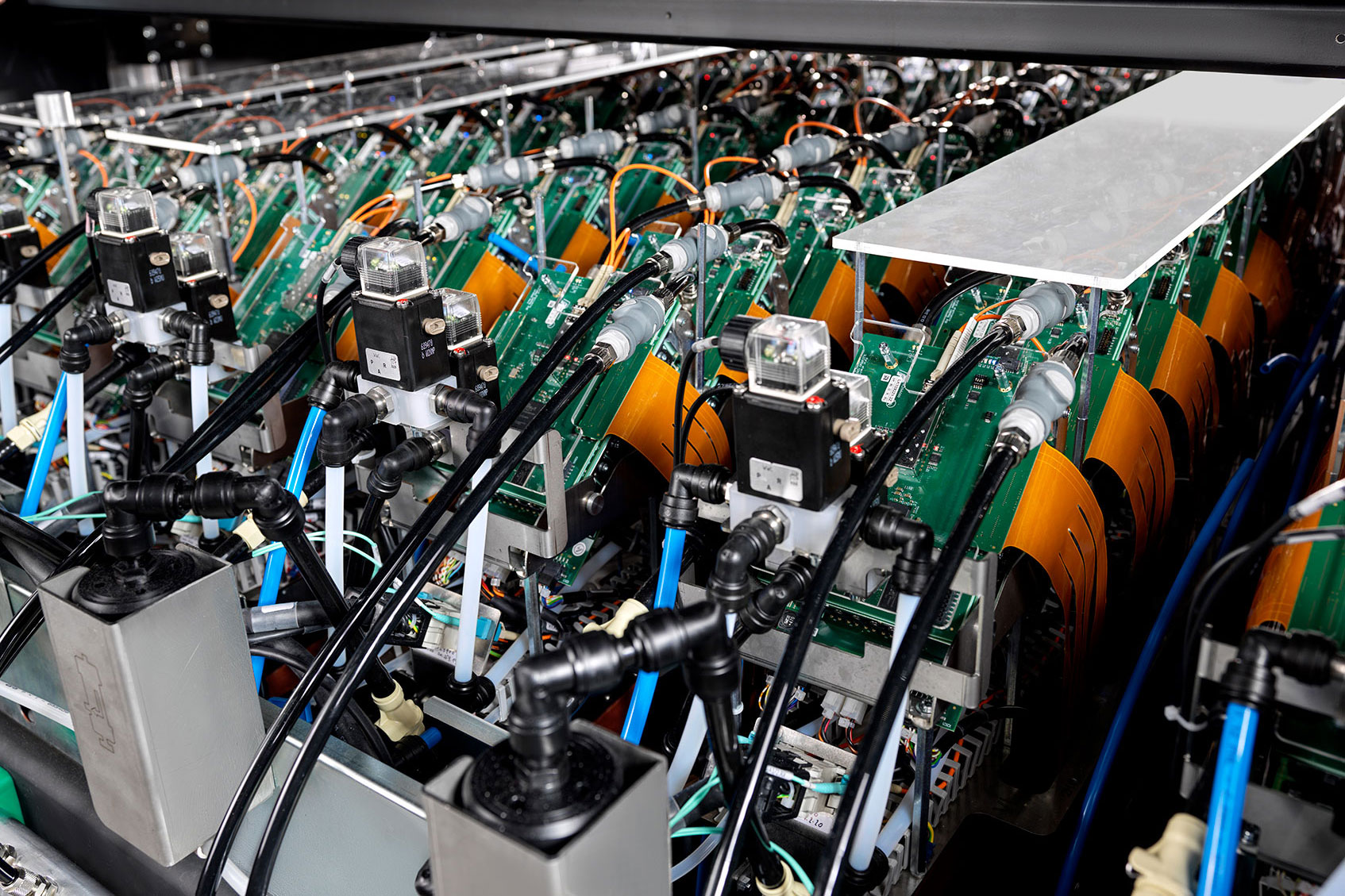

A well-engineered mechanical design combined with easily accessible sub-assemblies and selected components, offering unrivaled versatility, durability and reliability.

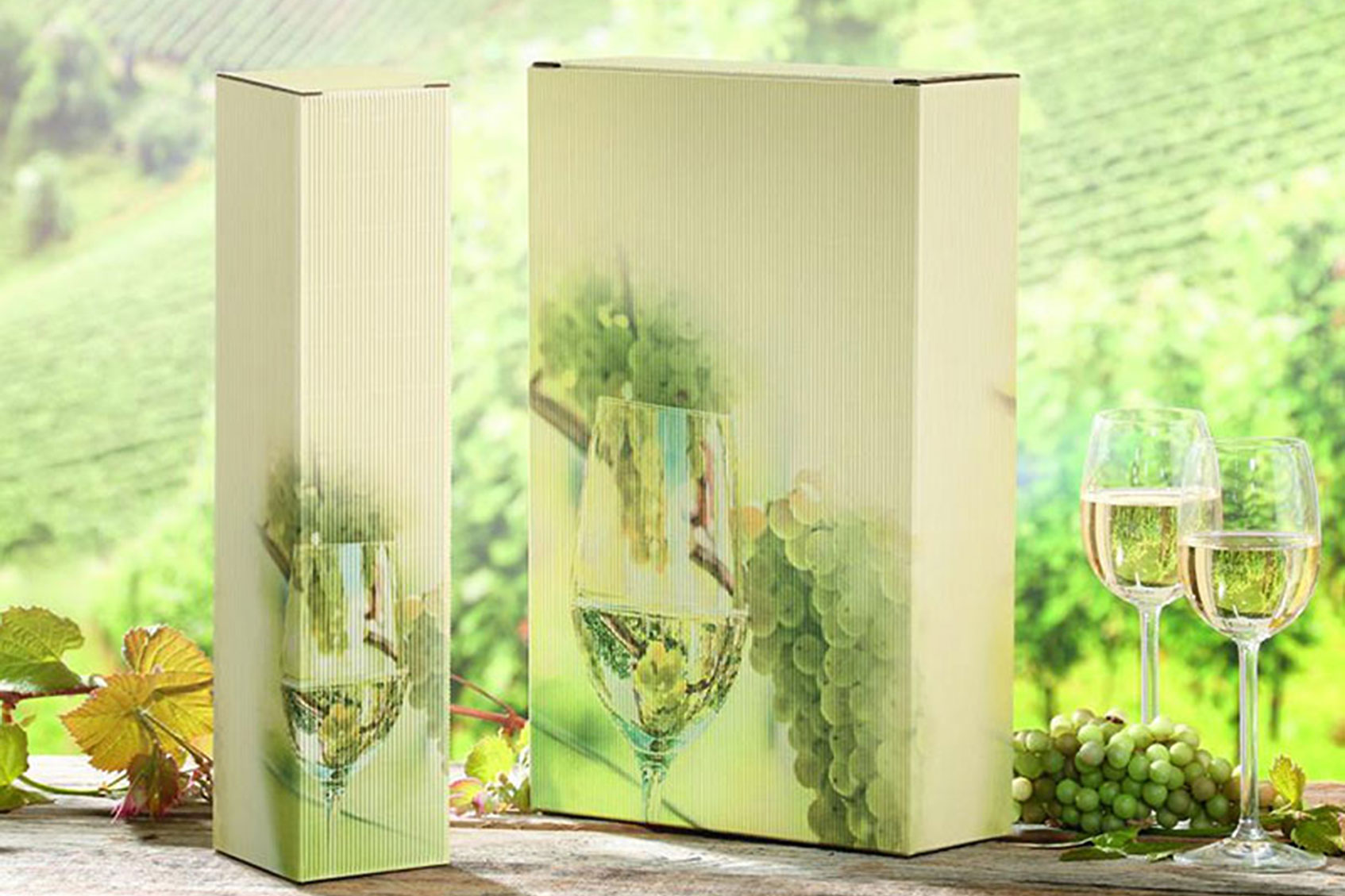

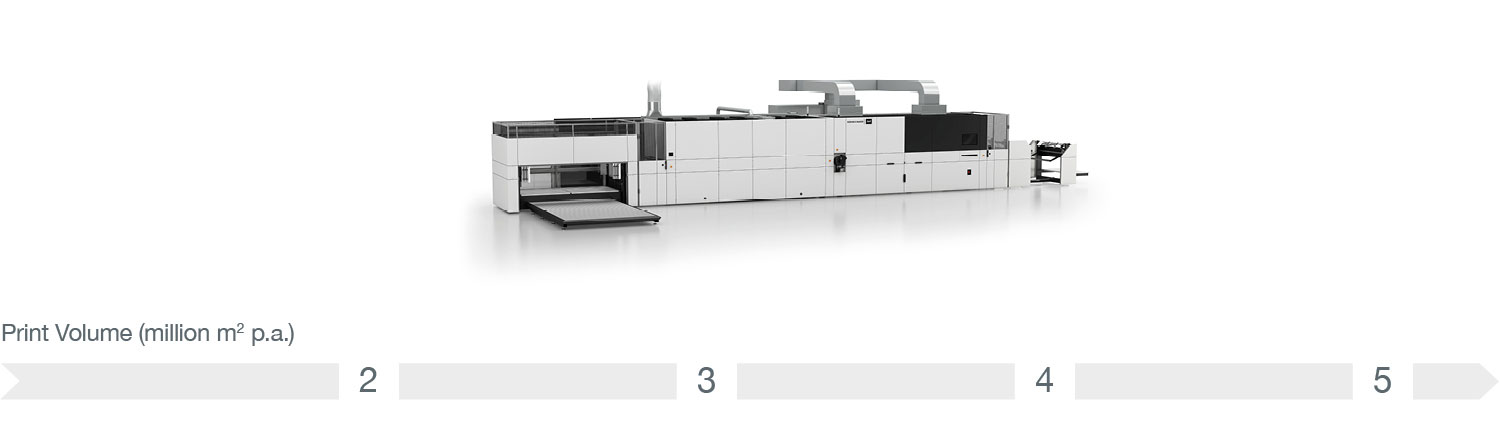

With the Delta SPC 130, Koenig & Bauer Durst is adapting single-pass technology to the corrugated board industry. The Delta SPC 130 combines a well-engineered mechanical design with easily accessible sub-assemblies and selected components to guarantee durable quality, high performance and reliability. It is a printing system that offers unrivaled versatility, low maintenance requirements and 24/7 reliability.