By Simon Lewis, Senior Vice-President, Marketing, Strategy &Business Development, Highcon Systems Ltd

Highcon Systems prides itself on being print agnostic.

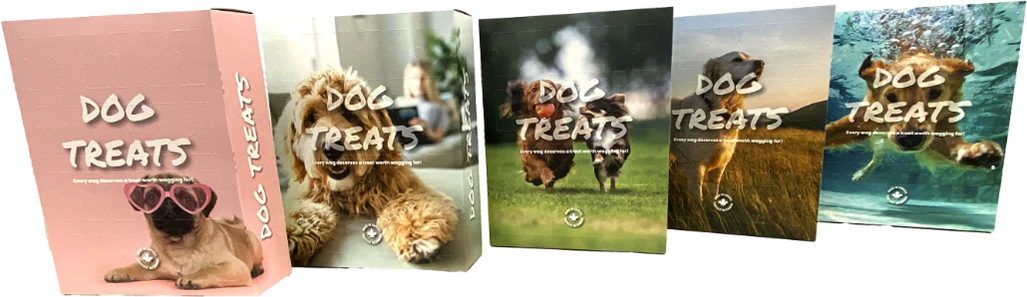

We can digitally die cut all kinds of print. And we take pride in working with everybody who is driving the digital revolution, enabling faster job turnaround, radical economics and great print quality.

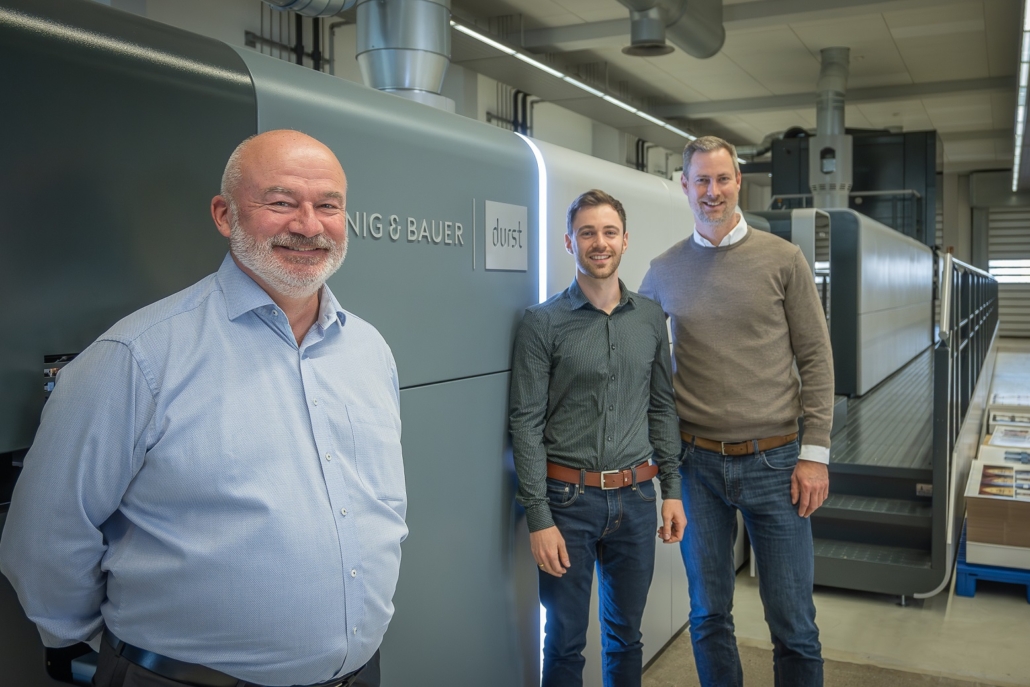

One of the companies we have been delighted to work with over the last few years has been Koenig & Bauer Durst, an important digital driver in the folding carton and corrugated space.

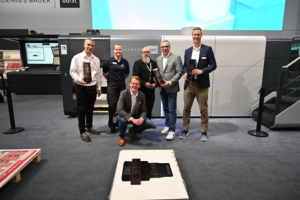

The power to inspire and unbox fresh new possibilities was perfectly demonstrated with Koenig & Bauer Durst and Scodix during drupa 2024.

The unique, in the moment, collaboration perfectly demonstrated how same-day turnaround pure digital production can quickly become a production reality.

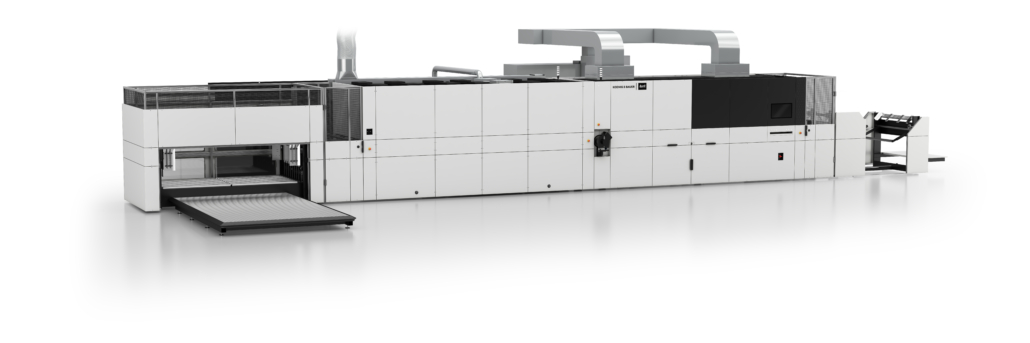

The examples of how packaging can transcend the ordinary included a premium whisky box printed on the Koenig & Bauer Durst VariJET 106, digitally embellished with Scodix’s Ultra 6500 SHD machine and completed with our Beam 3 digital die-cutting system.

These were live demonstrations of a true digital production platform, which perfectly illustrated what converters can achieve for their own customers and the kind of new value propositions that are possible.

The result: transformation into a complete shelf-ready package.

There is no time like the present. Mainstreaming digital die cutting, embellishing and printing.