By Matthias Krautgasser, Senior Product Manager, Koenig & Bauer Durst

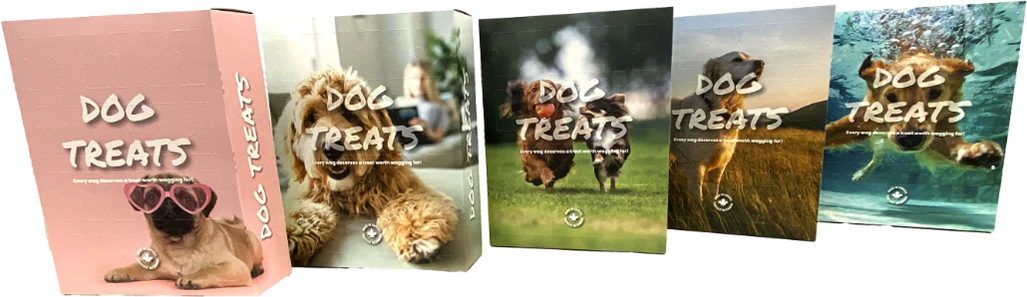

Versatile, flexible, fast and a perfect fit for converters wanting to step into the world of industrial printing in corrugated markets.

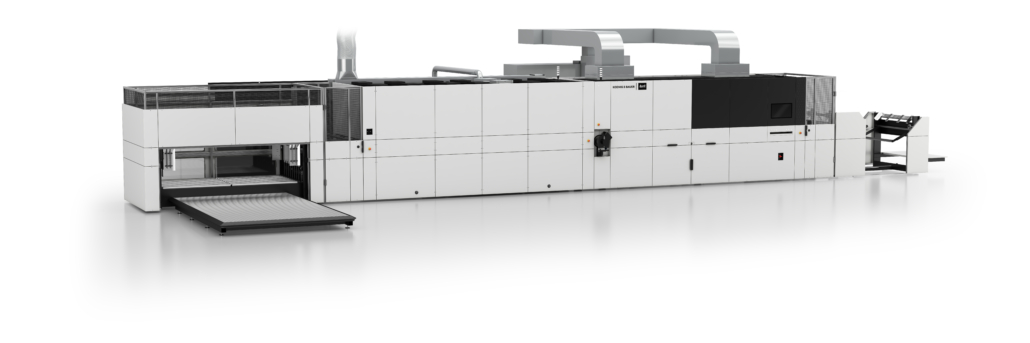

These are among the hallmarks for the Delta SPC Core that is the latest addition to our award-winning portfolio of single pass presses for the corrugated markets.

And we couldn’t be happier with the initial reactions from converters and customers to this newly launched press that is an entry-level ticket into digital printing within corrugated markets.

Based on Koenig & Bauer Durst’s established, market-proven Delta SPC 130 Automatic press, the Core is designed to grow with your needs, whether you’re scaling up in volume or adjusting to specific application requirements, such as special colors (orange, violet, green), water-based white, and primer.

Make no mistake: the Delta SPC Core may be ‘entry level’ but is still for industrial scale production – and fully scalable.

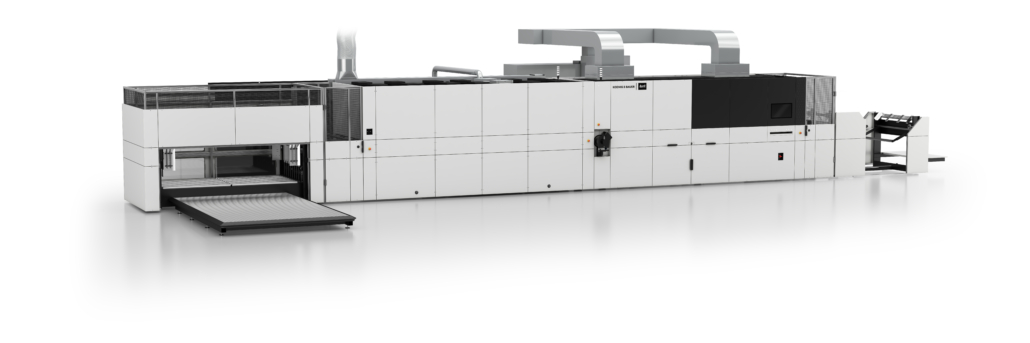

With a smaller footprint (measuring 20 metres from end to end), it will fit into many plants. The Delta SPC Core comprises four components: an easy-to-use feeder, main printer, a compact Eco+ energy-efficient drier and single-sheet stacker with a print size ranging from 1mm to 12mm in thickness.

The Delta SPC Core will deliver the series’ most impressive price performance ratio for converters with media sizes up to 1.30meters width (51 inches) by up to 2.80m (83 inches) length for corrugated box plants. It will be suitable for converters with annual production volumes of between 3 and 5 million square meters (32 and 54 million square feet) annually by printing 60m/min (197ft/min) on coated and 90m/min (295ft/min) on uncoated boards.

The Delta SPC Core is a clear answer to the requirements of the corrugated market for entry-level solutions and offers opportunities for growth in terms of new applications and productivity.

We can enhance the Delta SPC Core, transforming it into a high-performance powerhouse or an embellishment expert. The printer is engineered for precise customization to match your exact production needs. Proudly made in Austria, the home of the Delta SPC family.

This industrial production single-pass digital press is aimed at converters looking to transform to digital production or upgrade from their current digital system, including the possibility for in-field upgrades to increase throughput and/or application range.

Target customers will include box plants and companies doing display and boxes. Available now, lead times are between 6-8 months.

We expect to confirm details of our beta test customers soon with production starting in the first half of 2025.

Watch this space!