Guest blog by Thomas Goeke, Customer Experience and Marketing, Koenig & Bauer

Knowledge sharing, a celebration of achievements and future-forward approaches with partnerships based on trust… all among the overwhelmingly positive feedback to our recent Open House.

A heartfelt thank you to all the attendees at our ‘Expand Your Business Model’ event over two weeks at our Sheetfed division headquarters in Radebeul, Germany.

A heartfelt thank you to all the attendees at our ‘Expand Your Business Model’ event over two weeks at our Sheetfed division headquarters in Radebeul, Germany.

I have a strong belief in the need to inspire customers and provide value with our total one-stop shop approach.

It wasn’t just a showcase for die-cutting, folder-gluer and offset and digital printing processes, we were able to communicate our complete value proposition as a trusted partner.

Guests were able to see live demonstrations of integrated, innovative technology in an inspiring environment covering solutions in folding carton, label, commercial, and corrugated board sectors.

We covered everything from high-volume to short-run production, digital and showed the myKana digital ecosystem portal, including AI-supported products that add tangible added value for product optimisation.

One of the undoubted highlights was the “From Zero to Carton Hero” in 15 minutes, the timeframe it takes to complete a folding carton production value chain from sheet to finished product.

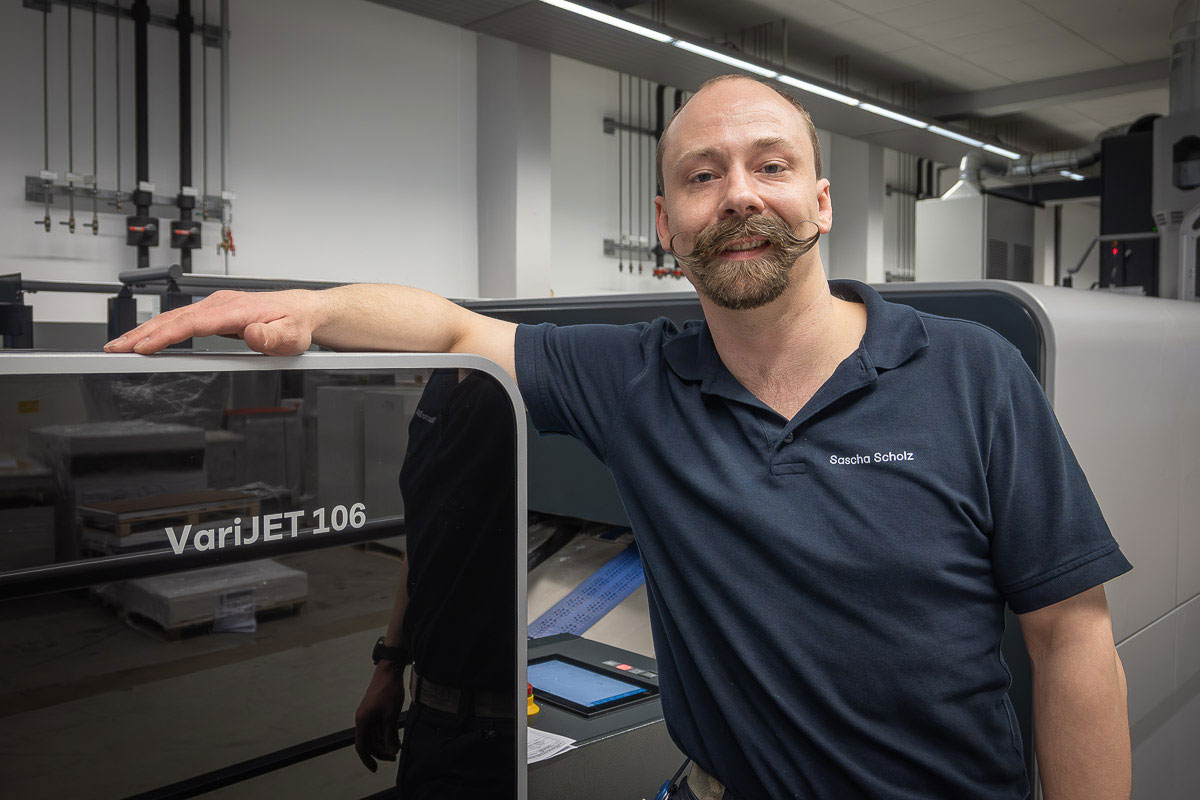

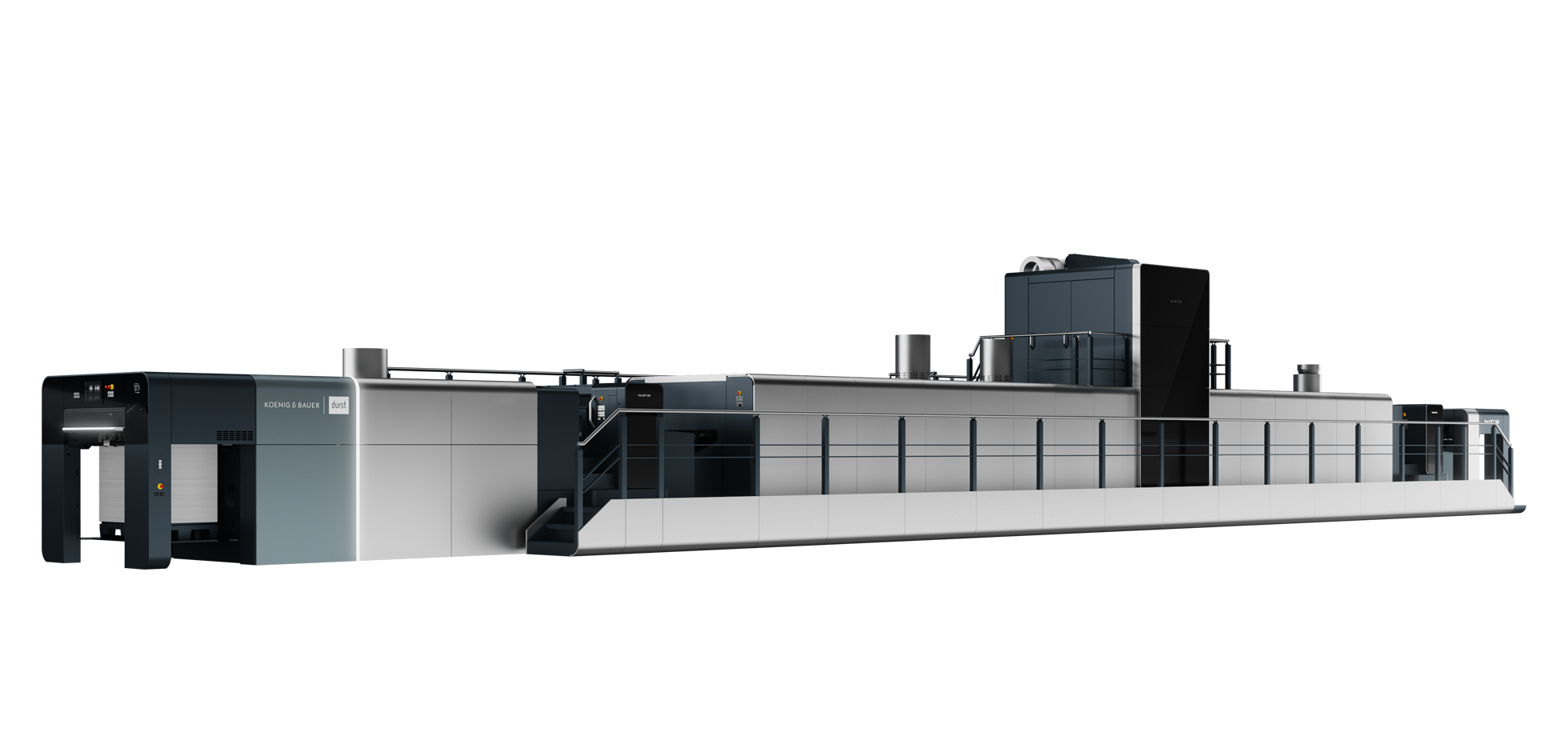

And of course, the VariJET digital production machine from Koenig & Bauer Durst was another!

And of course, the VariJET digital production machine from Koenig & Bauer Durst was another!

Witnessing the positive reaction from a fully focused audience every day was truly awe-inspiring.

As a one-stop solutions provider, we enable our customers to be successful.

We help them to look beyond products, understand the pain points and develop a profitable business model to help them grow with good guidance.

If you missed our “Expand Your Business Model” Open House, you can find out more here or here.

Guest blog by Ian Schofield, Packaging and Sustainability Specialist

Guest blog by Ian Schofield, Packaging and Sustainability Specialist Guest blog by Marc Hunsänger, Director Protection Technologies, Koenig & Bauer Vision & Protection

Guest blog by Marc Hunsänger, Director Protection Technologies, Koenig & Bauer Vision & Protection 1817: Koenig & Bauer is founded – the world’s oldest printing press manufacturer

1817: Koenig & Bauer is founded – the world’s oldest printing press manufacturer