Koenig & Bauer Durst’s VariJET 106 – first public showing is at drupa

Düsseldorf, Germany 29.05.24

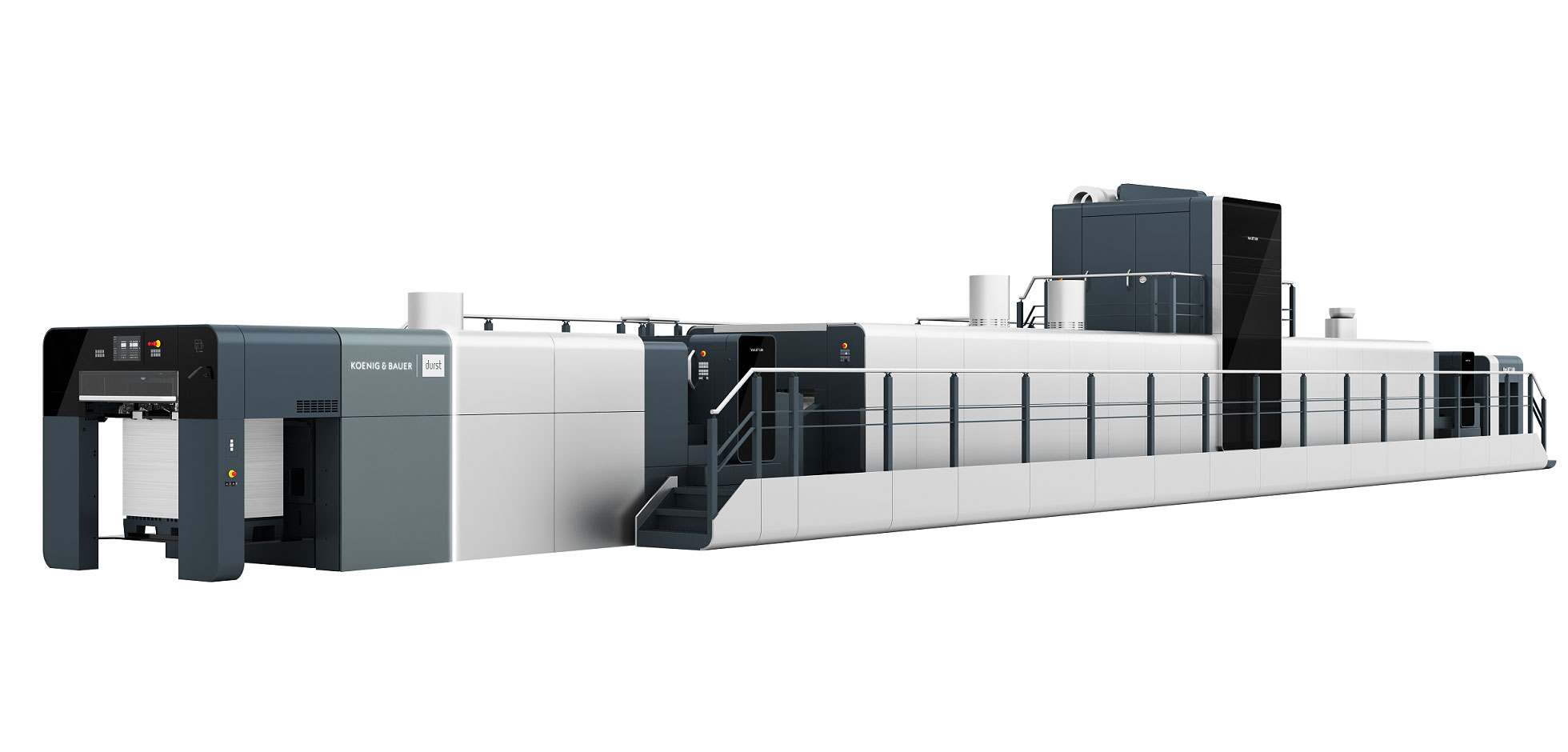

Koenig & Bauer Durst is demonstrating important advances with its digital press systems and software services in folding carton and corrugated markets on its booth (A-31-1, Hall 16) at drupa in Dusseldorf, Germany. The VariJET 106 single pass press, which uses market-proven technology developed by Durst and Koenig & Bauer, is making its public debut at the show, with regular production run demonstrations.

Visitors to the stand can take away a variety of printed samples from the Koenig & Bauer Durst stand. These include applications for markets such as pharmaceuticals, health and beauty products, as well as food and beverage. At drupa, Koenig & Bauer Durst’s VariJET106 is being shown in a hybrid configuration linked to Koenig & Bauer’s industry acclaimed Rapida offset press technology and workflow. There are multiple production runs throughout the show. Latest die cutting and folding gluer technology is also being shown live at the Koenig & Bauer neighbouring booth.

The market-proven Delta SPC 130 used in corrugated markets – another family member in Koenig & Bauer Durst’s single pass digital sheet-fed press portfolio – is also an important focus at drupa. A control station will is set up on the stand to demonstrate how the Delta SPC 130 works in a production environment utilising Durst Workflow and Durst Analytics.

Koenig & Bauer Durst’s Delta SPC 130 and VariJET 106 systems feature in daily shows at 11.45am and 2.45pm in English. There are also demonstrations of folding box production shows together with Koenig & Bauer with the VariJET 106 at 10.45am and 4:30pm in English as well as at 2:00pm in German.

Game-changing industry firsts such as the announcement of printing on mainly brown substrates with water-based digital white are being shown. Koenig & Bauer Durst is the first company in the world to offer digital white ink for corrugated substrates in primary food packaging. This creates new possibilities in packaging, for example printing on plain brown or lower grade white boards.

Daniel Velema, Managing Director of Koenig & Bauer Durst, said: “Visitors to our drupa stand in Hall 16 can be assured of a warm welcome. The VariJET 106 – our major digital development in folding carton markets – is now a reality. See for yourself this highly versatile machine that will be running samples on a regular basis. Some of these have been produced in Switzerland by SCHELLING AG, one of our customer sites. We’re also showing game-changing industry firsts such as our breakthrough involving printing on mainly brown substrates with water-based digital white for corrugated substrates in primary food packaging.

All Koenig & Bauer Durst presses use water-based food-safe inks & coatings that comply with all regulatory requirements.