Würzburg, Germany 10.01.24

Koenig & Bauer and Durst Group have committed to build further R&D capability in the joint venture company they set up almost five years ago to capitalize on the significant opportunities in folding carton and corrugated segments. The parent companies of Koenig & Bauer Durst GmbH will expand its operations in Radebeul, Germany.

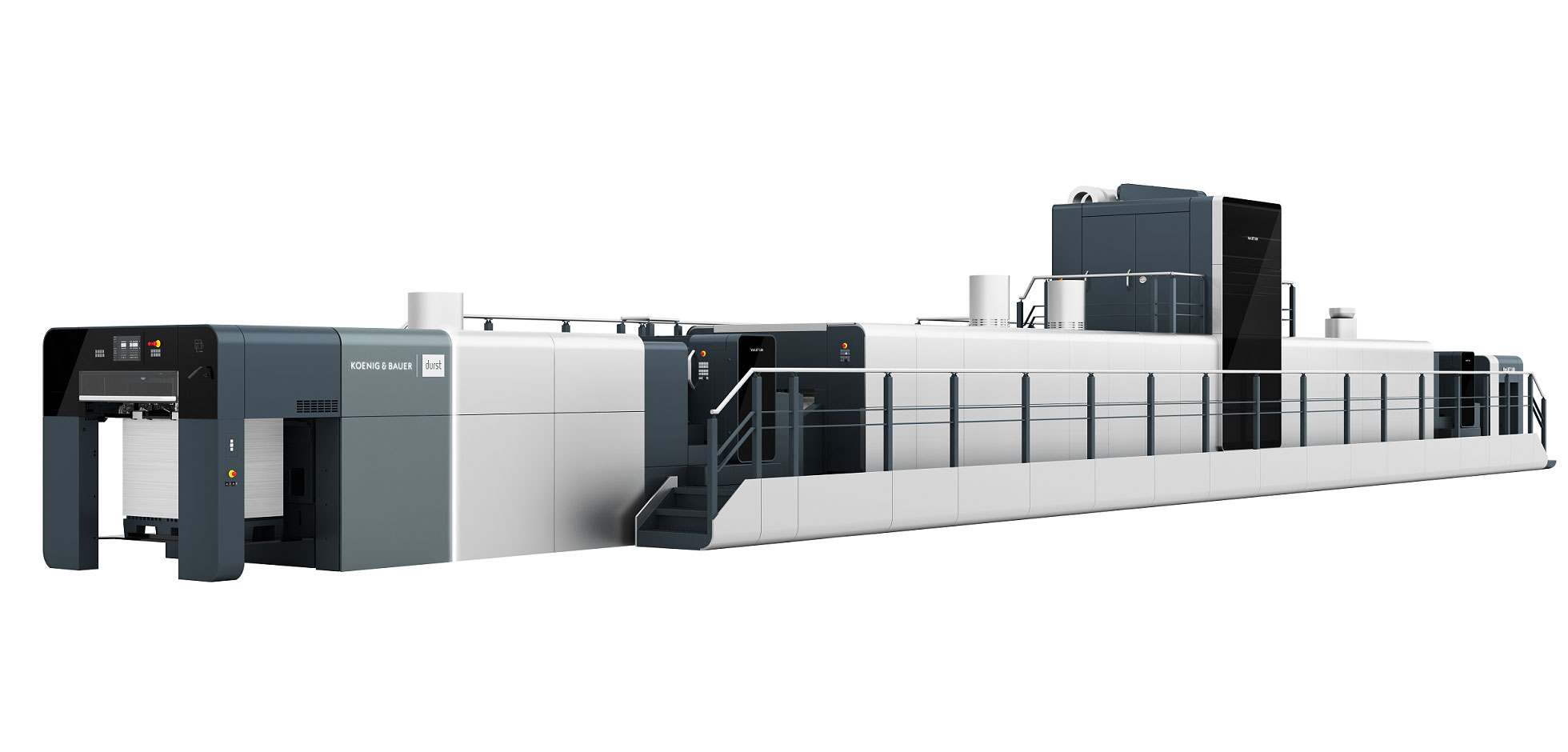

Koenig & Bauer Durst is a global market leader of single pass digital sheet-fed press systems and software services for the folding carton and corrugated industry. It leverages the capabilities and know-how of its parent companies to offer an unrivalled portfolio of digital printing machinery that includes the CorruJET and Delta SPC 130 systems for corrugated markets, as well the jointly developed VariJET 106 press for folding carton markets. All presses use water-based food-safe inks & coatings that comply with all regulatory requirements.

Robert Stabler, who has run the joint venture company since its inception, will stand down as Managing Director. He will be succeeded by Daniel Velema, who will join Koenig & Bauer Durst in February 2024. Daniel has extensive domain experience in the printing industry and managing consultancy and has held various senior level management positions. In his last role, Daniel was General Manager of the Prepress activities at XSYS Global, a leading supplier of printing plates, sleeves and prepress equipment for the packaging industry.

Daniel Velema said: “I am really looking forward to joining Koenig & Bauer Durst, which was set up by two technology pioneers in the printing and packaging markets and has a growing presence in the industry. Corrugated and folding carton printers/converters continue to digitize their production environment to increase efficiency, flexibility and to provide a better service to brands and retail. In the long term, this leads to significant cost reductions. Koenig & Bauer Durst’s machinery, software and services offering is well positioned to support and accelerate our customers’ journey and I look forward to working together with our customers, partners and suppliers.”

Christoph Gamper, CEO and Co-owner of the Durst Group, said: “We are looking forward to welcoming Daniel to Koenig & Bauer Durst to drive the company forward to the next stages of development. We see a huge opportunity to grow substantially over the next few years. Solid foundations have been laid with the successful launch of the VariJET 106 press, the most productive folding carton digital press on the market, as well as the adoption of our corrugated presses by some of the world’s most innovative and forward-looking corrugated companies. Robert has been instrumental in developing and leading the joint venture team that has developed high-end systems in fully automatic, industrial-scale production. We want to thank Robert for bringing the joint venture from an idea to a vibrant, standalone company.”

Ralf Sammeck, Koenig & Bauer Board Member and Sheetfed Segment CEO, said: “The spirit embodied by both companies in the joint venture continues to grow. Combining our strengths is driving digitalization in the packaging industry. In building on the initial foundations, we are increasing our capabilities in our R&D center in Radebeul, the headquarters of the Koenig & Bauer Sheetfed division. To take the joint venture to the next level, we are delighted to have appointed Daniel Velema as the new Managing Director from next February.”

Koenig & Bauer Durst expands its R&D capabilities at Koenig & Bauer’s Radebeul site.

Robert said: “Having led the joint venture company for almost five years, I have been proud to lead a committed team of professionals and establish ourselves as a real force in the industry. The fact that our two parent companies – Koenig & Bauer and Durst, two giants in packaging and printing – have committed to further R&D capabilities speaks volumes about the positive impact we have had in growing our presence significantly in corrugated and folding carton markets. These are ripe for digital transformation – and we have a growing customer base to prove that.”

He added: “I thank all staff, partners and our extremely loyal customer base who have shown unstinting as we have continued to grow and establish our global capabilities as a partner of choice across the world. Together with Daniel, there will be a significant handover period in what I am sure will lead to further success and profitability in the months and years to come.”