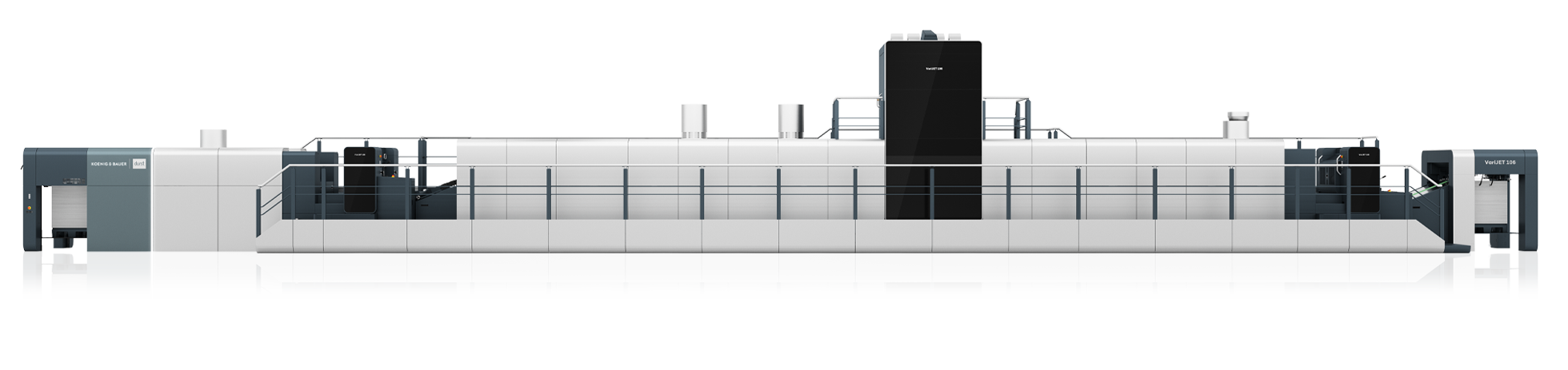

Don’t compromise.

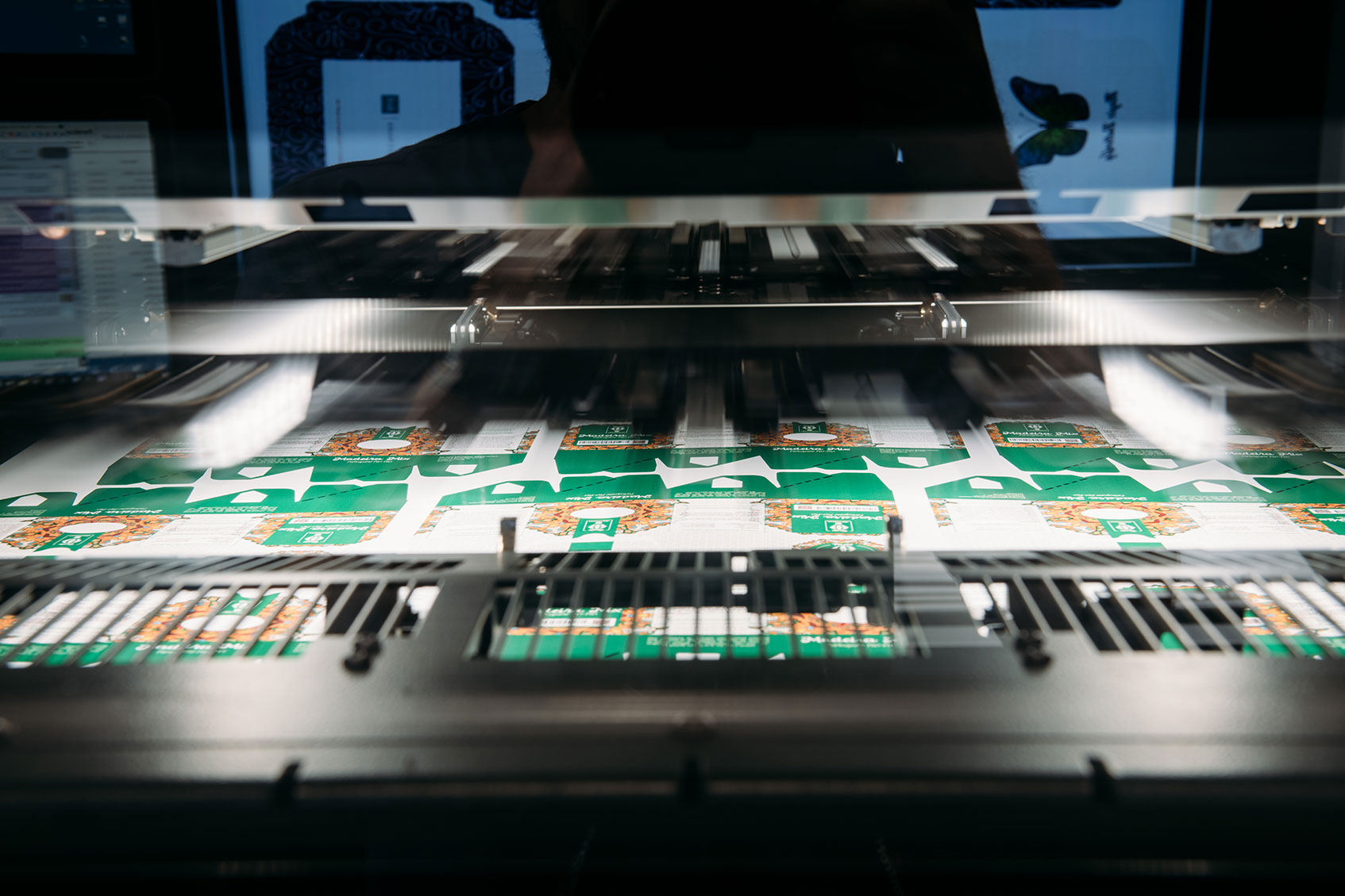

When it comes to folding cartons, get the best of both worlds.

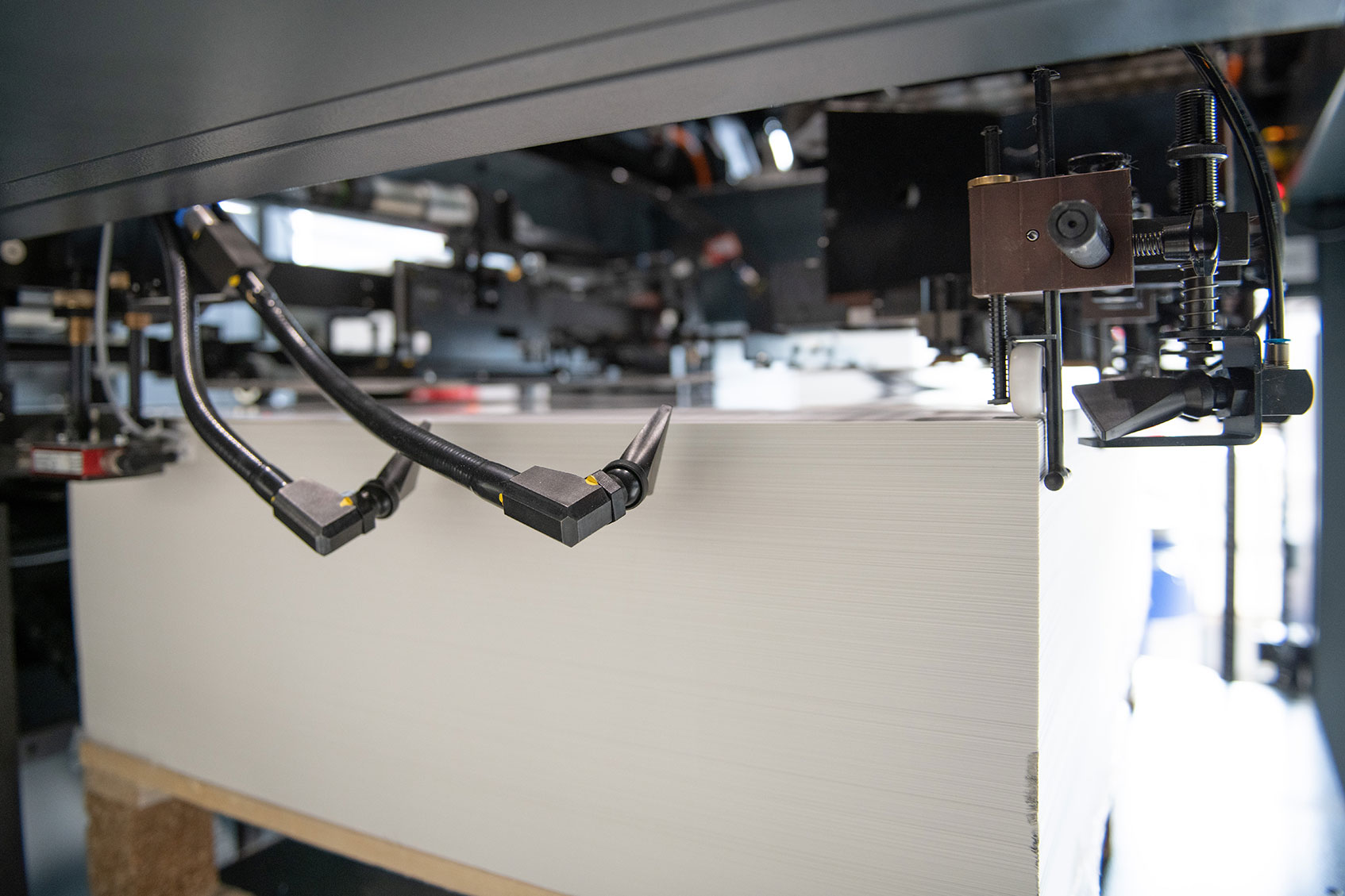

Digital inkjet presses provide opportunities like never before. The VariJET combines this know-how with the expertise of the leader in offset printing. We have reimagined the possibilities by combining the power of these two processes:

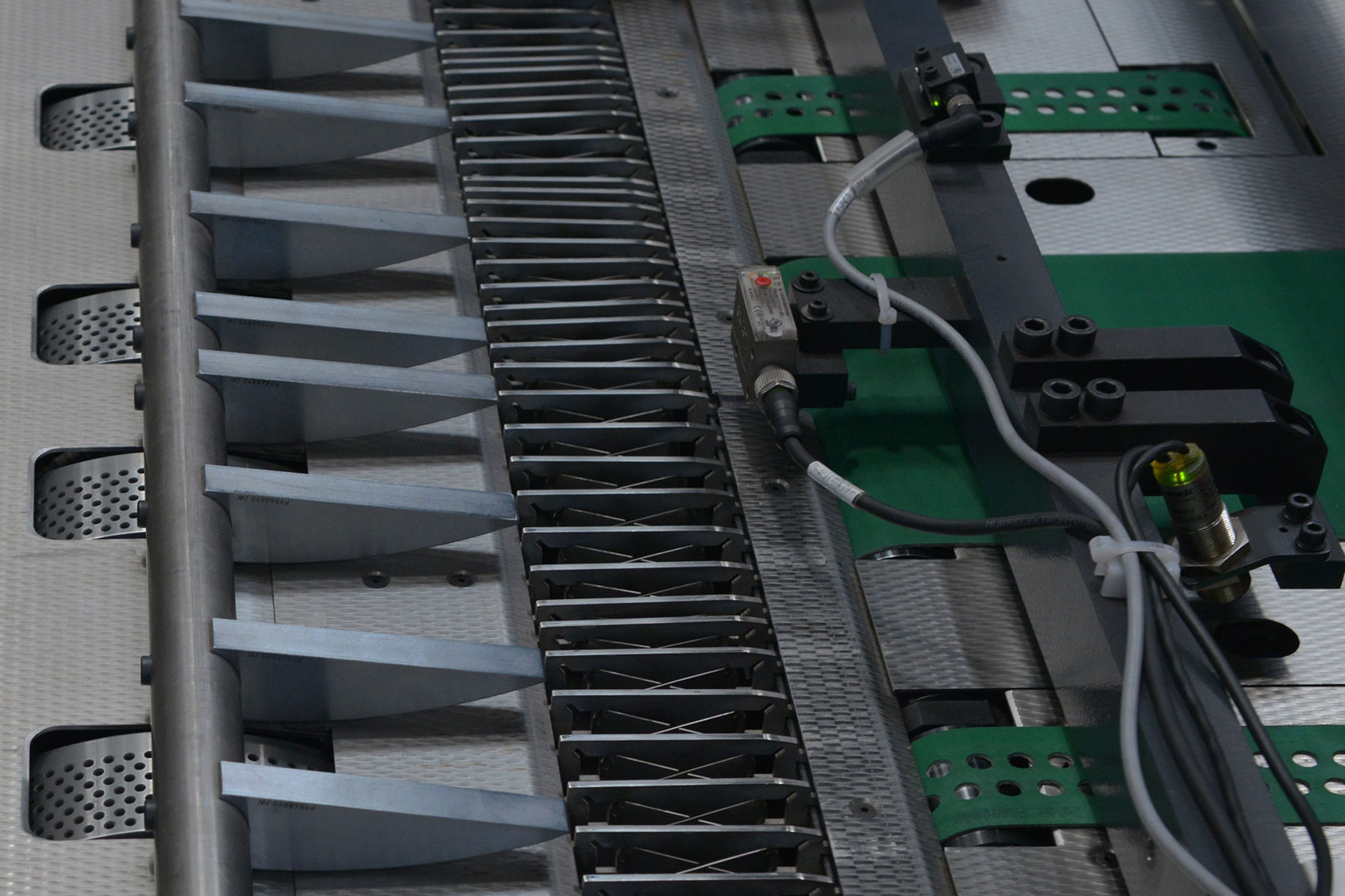

Offset substitutable quality with an extremely broad color gamut. Highly productive platform for customers from 0.5 to 2.0 million B1-sheets per month. Modular platform capable of utilizing offset and flexo functionality. Food-safe water-based inks to meet current and future regulatory and environmental standards.

This state-of-the-art, multi-purpose machine, created to meet the needs of personalization, combines the strengths of inkjet and classic offset printing for short runs and fast turnaround.