Koenig & Bauer Durst: Ein interessanter und aufstrebender Nachwuchs

By David Zwang, Principal Consultant, Zwang & Company

Historically, there has been much “quiet” intercompany collaboration in the manufacturing of press and finishing equipment. However, lately we have seen more outward collaboration between equipment manufacturers. Often, the collaboration ensures that they leverage each other’s strengths, while each of the companies retains their visibility and yet allows for a quicker development and go to market outcomes.

Historically, there has been much “quiet” intercompany collaboration in the manufacturing of press and finishing equipment. However, lately we have seen more outward collaboration between equipment manufacturers. Often, the collaboration ensures that they leverage each other’s strengths, while each of the companies retains their visibility and yet allows for a quicker development and go to market outcomes.

Koenig & Bauer, a leader in printing press manufacturing, and Durst, a manufacturer of advanced digital printing and production technologies, signed a 50/50 joint venture agreement in 2019. The signing of the agreement paved the way for the joint development and marketing of single-pass digital printing systems for the folding carton and corrugated fiberboard industry, with the resulting company being Koenig & Bauer Durst GmbH. The joint venture has its registered office in Würzburg and cooperates closely with both parent companies’ global network.

The JV

Historically there has been much “quiet” intercompany collaboration in the manufacturing of press and finishing equipment. There have been a few companies like Koenig & Bauer, Komori, Miyakoshi, Fujifilm, and others who have supplied transports or even complete machines to other equipment manufacturers to sell under their own brand. There have also been companies like Durst, Kodak, and others who supply imaging engines to transport manufacturers. However, lately we have seen more outward collaboration between equipment manufacturers. Sometimes it is through acquisition or merger, like the recent acquisition of Hunkeler by Muller Martini, or it is more complex, like Agfa’s acquisition of INCA, which already had a joint development relationship with BHS and SCREEN. Sometimes it is just a collaboration like those between HP and Koenig & Bauer on the HP T1100 and T700i presses or between Durst and OMET on a hybrid flexo label press, amongst others. Often, the collaboration ensures that they leverage each other’s strengths, while each of the companies retains their visibility and yet allows for a quicker development and go to market outcomes.

The Koenig & Bauer Durst JV is very interesting and almost unique in that both companies have a history of working with other companies, sharing their individual strengths. Each of the two are very innovative in their individual areas of skill and application and also aware of their limitations. As a result, their experience, drive, and current portfolio puts them in a very good position for growth and success.

The Portfolio

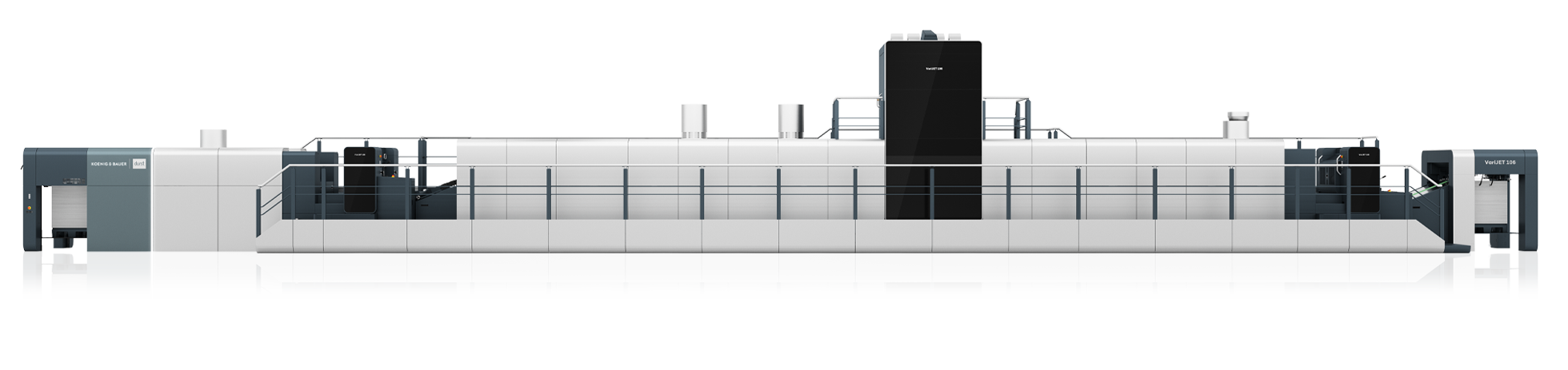

Today the joint venture portfolio currently comprises what was originally the Koenig & Bauer CorruJET 170, the Durst SPC 130 digital corrugated press as well as the VariJET 106 folding carton press, including all associated services and the ink business.

I had an opportunity to speak with Daniel Velema, who is the Managing Director of the JV, appointed in February, 2024. He confirmed that when he was appointed back in February, the strategic intent “was really about building a standalone independent organization while, if needed, obviously pulling knowhow and resources from the mother companies.” The organization is being built for folding carton and corrugated with a focus on digital print. For example, the VariJET 106 integrates inkjet technology into the platform of the highperformance Rapida 106 offset press. He currently sees the flagship VariJET 106 as offering the most initial opportunity for the JV and their customers.

The VariJET 106 is positioned to replace offset with a modular press platform that is capable of offering digital, offset, and flexo functionality. To date there are two installed and a third press going in. Like many of the transformational press manufacturers, analog or digital, they want to make sure that the first couple of customers are really successful, and that they get the product stable before a full rollout. Then they can also start thinking about what additional things need to happen with the product to make it even more successful. These could be changes in the specifications, market to positioning, etc.

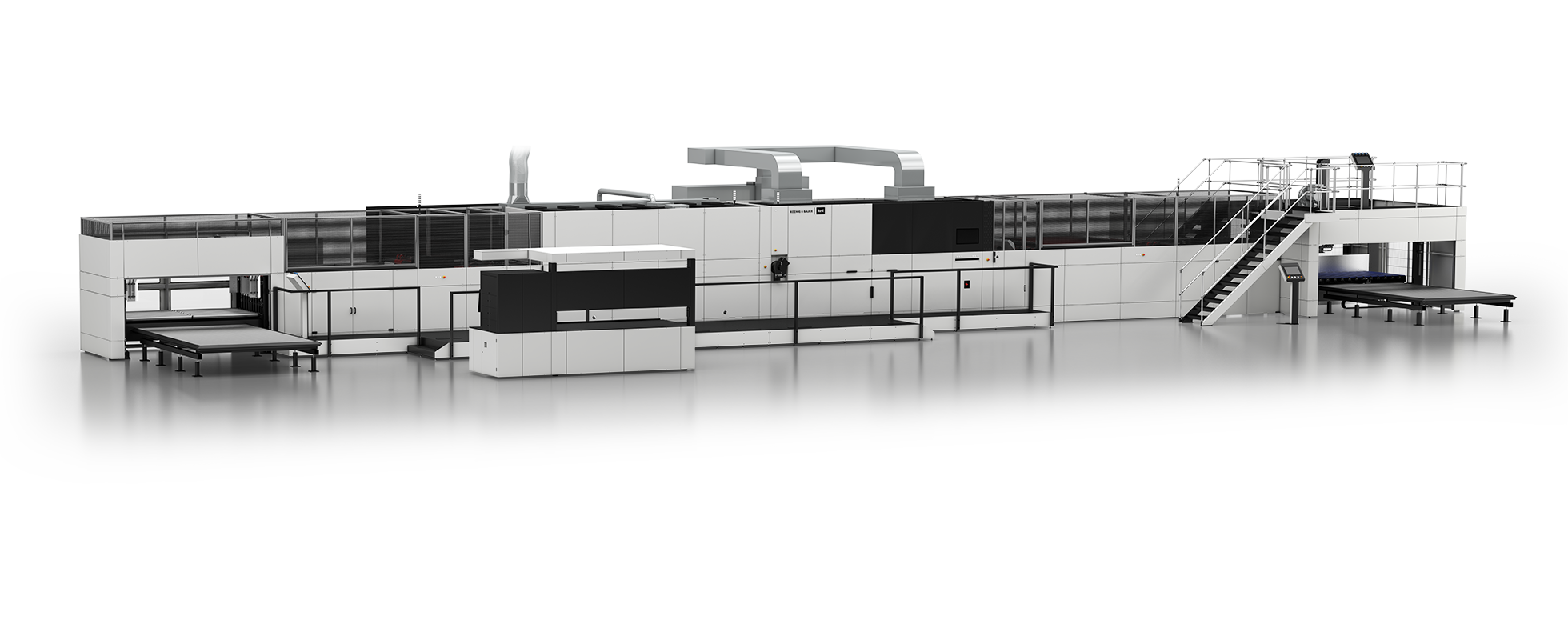

The Delta SPC 130, is a food-safe water-based inkjet press designed for non-impact corrugated printing which was initially released by Durst in 2019. When released it was a bit ahead of its time. However, there are a couple of “cool things” that they have introduced, which should broaden the appeal of the machine. One is a water-based digital white, which should help to move more flexo work onto a digital press. The other thing is that they took a hard look at the way they structure the portfolio.

They always had an “eco plus” configuration which was a slimmed down version of the “all in” automatic solution. However, now they want to drive the initial cost down even further so that people can start with digital printing with a lower-cost entry-level configuration with less automation, but with the capability to grow the configuration as they do. So, if a converter sees that the volumes are picking up and they get a better understanding of what applications they may be running, they can add new features to the press. For example, they may need a digital white or maybe they may need a primer or more colors, with this go to market model the converter can start building up their deliverable products and grow the press with it. “This way K&BD lowers the CapEx and gives it infield upgradeability,” said Velema.

At this time, Velema sees the CorruJET 170, which can print corrugated board up to 8mm thick, as a “bit of a niche product in that it is really after big volume digital printing on sheets,” and quite frankly the market is not really there as we can see generally in on-demand corrugated packaging at this time, but should be expected grow over time.

The Organization

As they look to build their organization for current and anticipated growth, they are investing in people, although they need to balance new hires against redundancies in the mother companies. Both Koenig & Bauer and Durst have extensive and talented teams. They are currently hiring application engineers to support their customers in the field, and looking for a technical program manager to support the VariJET. There’s a new service manager coming on board, and they are looking into expanding their capabilities in inks and software.

Geographically, they have been focused on North America and Europe to date. However, they are seeing a lot of interest in Asia Pacific and Latin America, so they are opening those areas up as well.

With the strengths of Koenig & Bauer, Durst and the JV, and if drupa traffic was any indication of the general interest, they can expect a strong future.

First published in: