By Wolfgang Zeug, Lead Print Instructor, Koenig & Bauer

Printing at drupa 2024 was the highlight of my career so far. While the show was busy and demanding, it was an incredibly positive experience overall, especially as the team worked so well together – before, during and after the event.

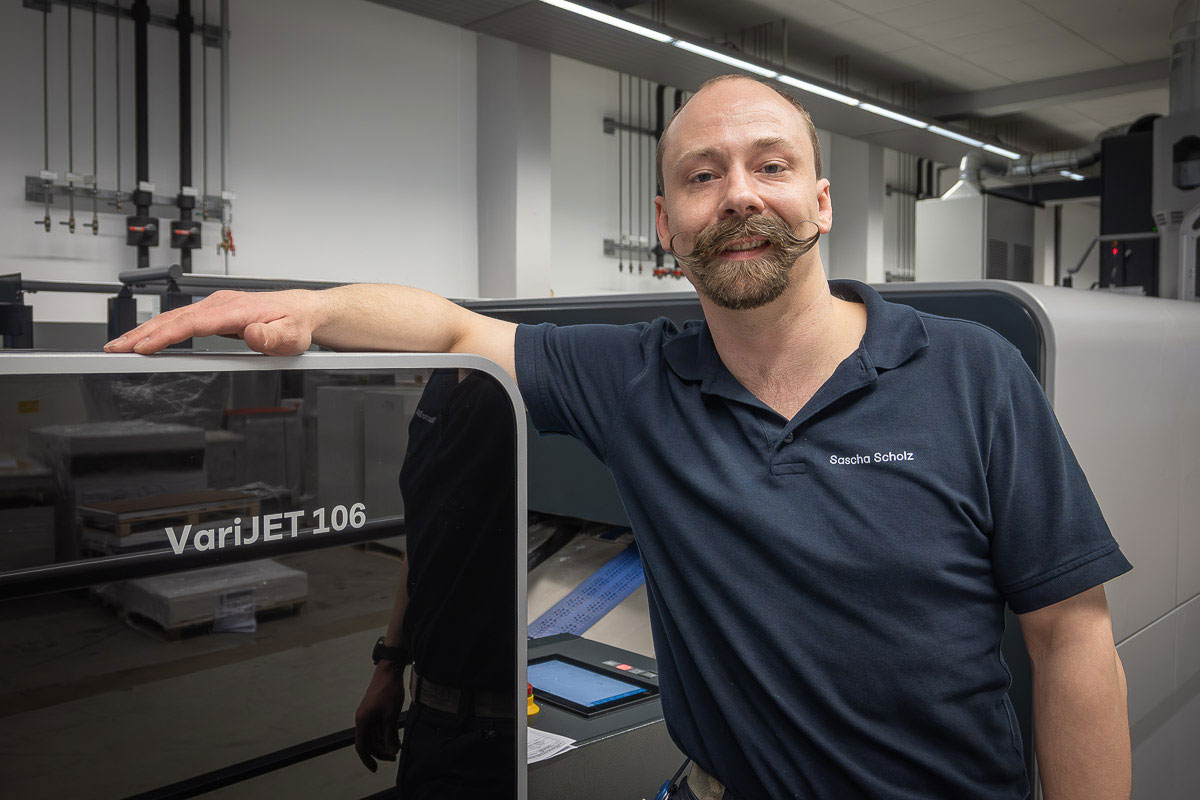

It was fantastic to see how much interest there was in the VariJET 106, the first jointly developed product by Durst and Koenig & Bauer.

It was insightful to hear the questions the visitors had and see their response to the world maps we were printing. In fact, the supplies of the maps always ran out very quickly.

I joined Koenig & Bauer as an apprentice in December 2006 and have been working on the VariJET 106 throughout its development. In the early days, it was very exciting to help with the development, to be a part of the decision-making process, and to watch when ideas were successfully implemented.

Being part of the team and refining the evolution of the VariJET has been a privilege, and I have been enormously proud to be a part of the process that has elevated the print quality to the results we consistently achieve today.

I’m also a print instructor for the Koenig & Bauer large format Rapida 145 or Rapida 164 presses. Initially I was a little worried about running the computer-based VariJET but it was very straightforward. Inputting the information is simple and creating high quality output is easy.

However, there are always ways to improve the capabilities of the press and there is so much potential with regards to handling variable data and the flexible production of small print runs.

Its versatile completion of colour rich results is impressive and always well received at shows and our dedicated demo centre at the Koenig & Bauer Sheetfed division headquarters in Radebeul, Germany.

As the same time, it is always amazing to see how customers can sometimes be inspired by digital printing in the demo centre.

It might be a standard demo, or a customer-focused demo, but it is so rewarding when customers start to see what could be possible for their operations.

All my colleagues at VariJET are doing a very good job, not just those who were involved at drupa. In other words, also those from Service who look after the machines at the customers’ premises.

I am incredibly proud to be part of this unique collaboration between market-leading companies in the printing and packaging industry.

Guest blog by Ian Schofield, Packaging and Sustainability Specialist

Guest blog by Ian Schofield, Packaging and Sustainability Specialist