Koenig & Bauer Durst GmbH

Friedrich-Koenig-Str. 4

97080 Würzburg

Alemania

Teléfono: +49 931 909 0

Email: info@koenig-bauer-durst.com

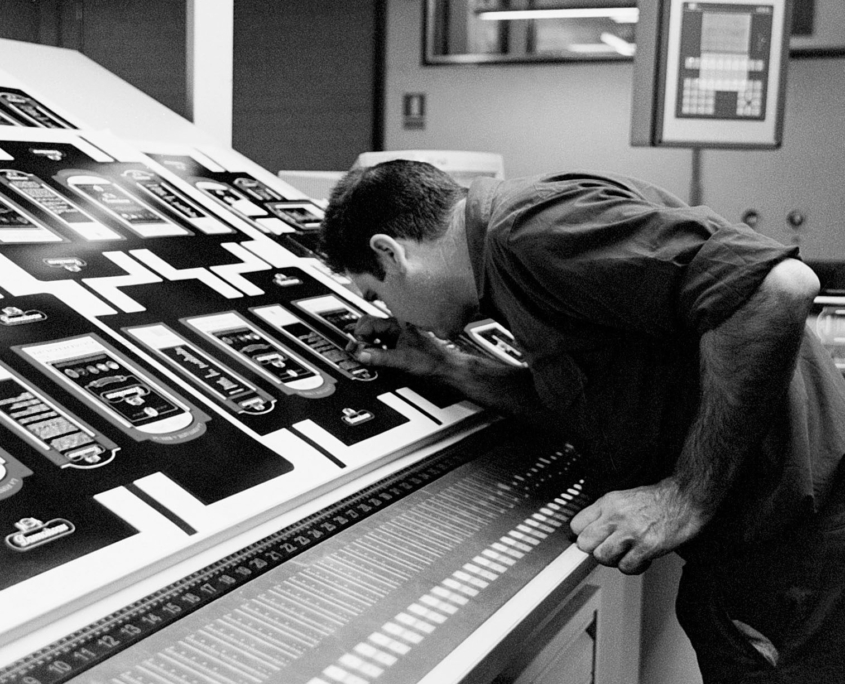

By Wolfgang Zeug, Lead Print Instructor, Koenig & Bauer

Printing at drupa 2024 was the highlight of my career so far. While the show was busy and demanding, it was an incredibly positive experience overall, especially as the team worked so well together – before, during and after the event.

It was fantastic to see how much interest there was in the VariJET 106, the first jointly developed product by Durst and Koenig & Bauer.

It was insightful to hear the questions the visitors had and see their response to the world maps we were printing. In fact, the supplies of the maps always ran out very quickly.

I joined Koenig & Bauer as an apprentice in December 2006 and have been working on the VariJET 106 throughout its development. In the early days, it was very exciting to help with the development, to be a part of the decision-making process, and to watch when ideas were successfully implemented.

Being part of the team and refining the evolution of the VariJET has been a privilege, and I have been enormously proud to be a part of the process that has elevated the print quality to the results we consistently achieve today.

I’m also a print instructor for the Koenig & Bauer large format Rapida 145 or Rapida 164 presses. Initially I was a little worried about running the computer-based VariJET but it was very straightforward. Inputting the information is simple and creating high quality output is easy.

However, there are always ways to improve the capabilities of the press and there is so much potential with regards to handling variable data and the flexible production of small print runs.

Its versatile completion of colour rich results is impressive and always well received at shows and our dedicated demo centre at the Koenig & Bauer Sheetfed division headquarters in Radebeul, Germany.

As the same time, it is always amazing to see how customers can sometimes be inspired by digital printing in the demo centre.

It might be a standard demo, or a customer-focused demo, but it is so rewarding when customers start to see what could be possible for their operations.

All my colleagues at VariJET are doing a very good job, not just those who were involved at drupa. In other words, also those from Service who look after the machines at the customers’ premises.

I am incredibly proud to be part of this unique collaboration between market-leading companies in the printing and packaging industry.

By Mark Richards, Sales and Business Development Director, Schumacher Packaging Birmingham

Consumers take just seconds to make a purchasing decision. That choice is informed by many factors shaped by identifying a need, undertaking an initial search and evaluating the options available.

An essential part of that process is brand trust and with that brand recognition. Consumers immediately connect with a name, logo and colour, and their ability to register

that is empowered by good packaging design.

Impactful design considers and includes all the elements that register with, and entice, customers. It also ensures the packaging is fit for purpose and adheres to the required regulations.

High quality, colour rich print is essential to reinforcing the brand’s image and maintaining consumer trust.

Digital print can deliver this alongside the ability to produce short runs or highly customised applications. It can enable brands to develop limited editions or seasonal versions to respond to demand opportunities.

It can also help a brand strategically place itself in the marketplace. Is it a premium, mid-range or budget brand? How can buyers easily know that? Making it obvious helps achieve the sale. It also helps with clear differentiation and that maximizes visibility.

The flexibility of digital print was one of the reasons why Schumacher Packaging’s Birmingham site installed the group’s fourth Delta SPC 130 from Koenig Bauer & Durst. It was the first six colour FlexLine Eco+ industrial production press to be installed and it can print on uncoated with speeds up to 80 meters per minute, which equates to around 10 million sq/m for uncoated per year.

Keen to see how your brand can benefit from digital print? Contact us. And make sure you visit our stand (76) at Packaging Innovations at the NEC in Birmingham on February 13-14.

Madrid, February 07, 2025_ Petit, a family-owned leader in the corrugated cardboard production and conversion sector in the Iberian Peninsula, has reached an agreement with Koenig & Bauer Durst to start the digitalization of point of sale (POS) and packaging production.

This agreement begins with the installation of a single-pass digital inkjet Delta SPC 130 printing line supplied with water-based inks, which will be carried out during the first half of 2025.

With this strategic investment, Petit reaffirms its commitment to sustainability and technological progress, consolidating its position as a leader in innovation and digitalization in the sector, while teaming up with a supplier that has the full back-up off two leading companies in their respective markets, Durst and Koenig & Bauer.

About Petit

Founded in 1933, Petit is one of the leading companies in the production and conversion of corrugated cardboard applications in the Iberian Peninsula. Its commitment since its foundation has been its commitment to constant adaptation to the needs of the market, guaranteeing the most demanding quality standards.

From L to R – Neil Williams, Northern UK & Ireland Sales Manager (Durst UK & Ireland); Daniel Velema, Managing Director (Koenig & Bauer Durst); Bauke van der Molen Kuipers, Departing Interim Managing Director (Schumacher Packaging Birmingham); Ian Walker, Digital Print Team Leader (Schumacher Packaging Birmingham); Matthias Krautgasser, Senior Product Manager (Koenig & Bauer Durst); Darren Melville, Managing Director (Schumacher Packaging Birmingham); and Saad Ahmad, Finance Director (Schumacher Birmingham).

Radebeul, Germany 04.02.2025

Koenig & Bauer Durst has announced that Schumacher Packaging Birmingham has started full commercial digital production with its Delta SPC 130 single pass high volume digital press for corrugated markets.

The FlexLine Eco+ with six colours is the first installation in the UK and will be a central focal point as Schumacher Packaging expands its presence in UK markets as one of the UK’s leading plain and printed cardboard manufacturers.

Koenig & Bauer Durst’s Delta SPC 130 – part of its portfolio providing the most automated, productive, single pass water-based presses suitable for food packaging – will be a key presentation focus for Schumacher Packaging Birmingham with its presence at Packaging Innovations (Stand K76) at the nearby NEC on February 13-14. Jochen Sproll, Koenig & Bauer Durst’s Strategy & Business Development Manager, will also be on the stand.

Schumacher Packaging Birmingham, together with Koenig & Bauer Durst, will also be hosting an official Open Day at its plant on March 13 from 09.00 to 14.00.

The Koenig & Bauer Durst Delta SPC 130 in Birmingham is the fourth taken on by Schumacher Packaging. Two others are at its headquarters in Ebersdorf, Germany, and the another is at Saica in Wroclav, Poland, formerly Schumacher Packaging. They also have six-color capabilities. The installation is at the heart of a €30 million euro investment that also involves upgrading its Birmingham manufacturing base and two nearby warehouses.

Koenig & Bauer Durst’s FlexLine Eco+ press features an eco-plus drier that reduces drying times to cut energy consumption and associated costs, as well as speeding up productivity for maximised capacity. The Delta SPC 130 can print on uncoated materials with speeds of up to 80 meters per minute.

Darren Melville, Managing Director of Schumacher Packaging Birmingham, said: “As an innovator and pioneer in the industry, we want to show new ways of working towards sustainable production. And moving to sustainable, cost-saving digital production is a centrepiece of our strategy, which is why we are delighted to have launched full-scale commercial digital production with the Delta SPC 130 from Koenig & Bauer Durst. This is a true partnership.

“As consumers become more environmentally conscious, brands are under increasing pressure to adopt eco-friendly packaging solutions. Many are working towards ambitious 2025 extended producer responsibility (EPR) for packaging targets. This is where the best of corrugated board and digital print can converge to deliver recyclable packaging with zero-waste designs.”

Daniel Velema, Managing Director of Koenig & Bauer Durst, said: “With the increasing emphasis on sustainability, companies such as Schumacher Packaging recognize the huge benefits that digital brings with highly automated systems in corrugated packaging and board markets. They and their customers can see the benefits of changing from offset and flexo, particularly as run lengths are getting smaller and order lead times become ever shorter.

“Digital printing, in essence only printing what you want, when you need it, has always been a technology with strong sustainability credentials and an opportunity to reduce paper consumption. The ability now to add paper weight reductions to further lower cost and consumption is also a very powerful argument for digital transformation.”

The Delta SPC 130 – a Schumacher Packaging success story

By Christian Jank, Process Engineer, Sheetfed, Koenig & Bauer

Coming originally from an offset background and having spent many years in digital print applications, I’ve seen the best of both worlds.

Digital printing is reshaping the folding carton market by enabling rapid, flexible, and sustainable production solutions. While it’s not a replacement for traditional methods, its role is growing, particularly for shorter runs, design flexibility, versioning, and agile production needs.

A large portion of folding carton converters see the future of the packaging industry as a hybrid approach, combining digital and conventional printing to balance cost, scale, and customization needs.

The feedback I’ve received indicates that the VariJET 106 single-pass press, a collaborative development by Durst and Koenig & Bauer specifically for the folding carton markets, will transform business operations.

Among its big strengths are the outstanding color-to-color registration and machine stability ensuring high uptimes. Customers are amazed that you can print black negative in as little as 4pt font even with the densest black. It’s particularly useful with barcode work when every job is different.

All-in-one production – particularly with embellishment possible for anything from tobacco packaging to pharmaceutical applications – is also becoming increasingly important. We have a unique position with this level of productivity (our VariJET 106 runs at 5,550sph) in line embellishment in B1 digital format.

One Koenig & Bauer customer from the UAE we saw at drupa was blown away by the capabilities of the VariJET 106 on carton boxes for whisky, which included vinyl on uncoated paper. Their feedback to the dark green, embellished tint used were extremely positive.

Another customer visiting our VariJET Demo Center was impressed by the color registration and quality of the hair coloration on the printed packaging for a major brand. Critical to the success was achieving the grey balance.

People may ask, ‘Why invest in digital?’ To me, it is simple: Digital packaging printing on the VariJET eliminates time-consuming processes such as color matching for new packaging products. From concept to market-ready product, the timeline will be reduced from weeks to mere days.

The quality is there to meet the demands of the packaging industry. Digital printing in folding carton markets has an important future, one I’m glad to be part!

By Anthony Memme, Digital Print Manager, Atlantic Packaging Products Ltd

Is your business achieving its full potential? Is it creating fresh opportunities?

At Atlantic Packaging Products, much of our success today stems from a renewed focus fueled by our investment in the Koenig & Bauer Durst Delta SPC 130 technology, which utilizes food-safe, water-based inks.

Printing high quality graphics directly onto uncoated and brown kraft corrugated sheets was not possible before. But today we have the ability to easily customize packaging designs and digitally printed packaging, incorporate variable data and tailor applications to different customer segments. All of which can enhance brand identity.

We have design freedom to explore innovative and creative designs with an array of colours and finishes that can be used to bring imaginative visions to life cost effectively.

Short-run production flexibility means we can produce the exact quantity required and undertake repeat orders without incurring excessive costs, plus ensuring a faster time to market. While the ability to optimize the supply chain allows us to print on demand to meet very specific timescales to reduce inventory costs and eliminating unnecessary waste.

Working closely with Koenig & Bauer Durst to ensure we are maximising the digital opportunities that are possible with the Delta SPC, these are just some of the benefits we have been educating customers about. We have also been helping them explore what is possible. We also have a comprehensive array of application samples in our show room inspiring creativity and affirming how we can unlock a world of possibilities by offering our customers cost efficient, sustainable packaging with short turnaround times.

You can see how a video of our Delta SPC 130 here: Corrugated Digital Printing & Packaging Solution – Atlantic

Contact us to find out how we can help your business maximise in a new world of opportunities with digital packaging production Atlantic Packaging Digital Printing

Ralf Sammeck, CEO of Koenig & Bauer Sheetfed, and Daniel Velema, Managing Director, Koenig & Bauer Durst in the new dedicated hall in Radebeul

Radebeul, Germany 14.01.2025

A unique opportunity to see and test digital, offset and post-print production on a single site is now a reality with the opening in Radebeul, Germany, of a dedicated hall for the VariJET 106, the hybrid press for folding cartons jointly developed by Durst and Koenig & Bauer.

Customers and visitors can now bring their own print files and substrates to see for themselves the flexibility, sustainability and cost-competitive opportunities afforded by Koenig & Bauer Durst’s VariJET 106 modular, single-pass press, which had its public debut at drupa. The 700 square meter hall is part of the global Customer Experience Center at Koenig & Bauer’s Sheetfed division headquarters, near Dresden, which is now part of the Paper & Packaging Sheetfed Systems (P&P) segment.

“The new dedicated hall for the VariJET 106 digital, hybrid press for folding carton markets represents another important step in our evolution,” said Daniel Velema, Managing Director, Koenig & Bauer Durst. “The opening means the Customer Experience Center is the one and only place where you can see and test digital, offset and post-print production at a single site. This is where prospects from all over the world can test the VariJET 106 for themselves using their own files and substrates. This ability to advise across print and finishing technologies is driven by our ambition to first and foremost understand & support your business needs & opportunities, and talk about technology second.

“We showed at drupa what is possible with full digital – digital printing, embellishment and finishing. Now we would like to show guests the next steps in the digital revolution for folding carton markets. Reach out to your local representatives, we would love to welcome you to Radebeul. For those who haven’t been there yet, the Koenig & Bauer Customer Experience Center – for press and machine demonstrations, application testing, the development of new technologies and for training purposes – focuses on specialized areas of packaging like folding carton, commercial and label production.”

Daniel added: “Ever since the VariJET 106 Customer Experience Center opened, Koenig & Bauer Durst has been running back-to-back print tests with customers and brands from all key geographies being represented: North America, Europe and Asia Pacific. We are particularly pleased by the interest of Asian customers who don’t shy away from making the trip to Germany!

“Successfully tested applications include cosmetics, pharmaceuticals, healthcare and food. We work closely together and explore hands-on what Koenig & Bauer Durst can improve to better meet market demands.”

The VariJET 106, which runs 5,500 B1 sheets per hour, combines the best of both worlds – digital inkjet and classic offset printing. The VariJET 106 uses water-based inkjet inks (CMYK plus orange, green & violet), primers & coatings to provide the highest print quality at a most competitive cost level, while supporting current and upcoming food safety and sustainability regulation. It leverages on Koenig & Bauer’s standard high performance Rapida 106 platform and Durst printhead electronics, inkjet expertise and Durst workflow and RIP technology. This includes Durst Analytics, Smartshop and Workflow.

Koenig & Bauer and Durst first announced they had joined forces and set up an independent joint venture company in 2019. The VariJET 106 is the first product jointly designed and developed by the two companies. Already in production and part of the Koenig & Bauer Durst portfolio are the Delta SPC 130 Series and the CorruJET 170 Series – aimed at corrugated packaging.

The VariJET 106 in the new dedicated hall in Radebeul

Chris Lyons, President/Publisher Packaging Impressions & PPC (far left) and David Pesko, Event Director of the Digital Packaging Summit (far right), present Sandra Wagner, Vice President Digitalization at Koenig & Bauer, and Stephen Sanker, National Sales Director for Digital Web at Koenig & Bauer (US), with the award for the Best Folding Carton Case Study at the Digital Packaging Summit in Florida

Koenig & Bauer is extremely proud to accept the first-place award for the best folding carton case study at the tenth annual Digital Packaging Summit, held in Ponte Vedra Beach, FL in early November 2024. Its two top executives – Stephen Sanker, National Sales Director for Digital Web at Koenig & Bauer (US), and Sandra Wagner, Vice President Digitalization at Koenig & Bauer – successfully delivered a very compelling folding carton case study to the summit’s senior managers and business executives who want to understand how current and future digital production printing technology, software and solutions will impact their business and investment decisions.

Stephen Sanker says: “This is our second win in three years. We felt that we made a huge impact with converters showing them the impressive capabilities of Koenig & Bauer’s digital portfolio including the VariJET 106 digital sheetfed printing system, RotaJET digital web-fed printing system, the myKyana digital ecosystem, and our groundbreaking Connected Packaging solution. Our presentation of a real-life application fostered a lot of questions and interest, opening dialogue about planning and strategy. We were able to demonstrate how Koenig & Bauer has set itself apart and offer very effective tools.”

During the three-day event, experts presented cutting-edge digital solutions that are transforming the packaging industry. Sandra Wagner was one such expert who presented an analysis of how digital printing can open up new possibilities for companies of all sizes. She also shared valuable insights into how Koenig & Bauer is leveraging the latest technology to drive innovation and enhance the customer experience. Both Sanker and Wagner conducted a series of popular one-on-one meetings. Their message to converters was to embrace the future of industrial scale digital production while forging stronger connections between brands and consumers.

Koenig & Bauer’s massive knowledge in sheet and web-fed solutions fueled application developments in the folding carton segment offering unmatched industrial production volumes and brand level color surpassing all standards in the category. Its RotaJET high-speed industrial digital inkjet web press prints and produces with superior image quality, substrate versatility, and print volume. The VariJET 106 from Koenig & Bauer Durst integrates all the know-how and expertise by combining digital and offset so customers can have the best of both worlds for the ultimate hybrid printing system. The central customer portal, myKyana, offers data-driven productivity tools with real-time production data analysis to help to make smarter decisions faster for positive impact.

“This is a very important event on the digital packaging marketing calendar,” says Sandra Wagner. “It offers strategic-level insights into what printing and converting industry leaders should do to improve and optimize their business. We felt that the tremendous positive reaction we received from the attendees lets us know that we have the correct approach. The Digital Packaging Summit is the leading event for digital printing and digitalization.”

Interesting website: www.digitalpackagingsummit.com

Koenig & Bauer Durst GmbH

Friedrich-Koenig-Str. 4

97080 Würzburg

Alemania

Teléfono: +49 931 909 0

Email: info@koenig-bauer-durst.com

Koenig & Bauer Durst GmbH

Friedrich-Koenig-Str. 4

97080 Würzburg

Alemania

Teléfono: +49 931 909 0

Email: info@koenig-bauer-durst.com